Set Gemstone Using Laser Weld

Accuracy and efficiency offered by laser welding help to change the jewelry and fashion industry. Setting gemstones typically makes use of it since it provides safe connection free from damage to the stones or surrounding metal. Perfect in fashion for creating intricate designs on delicate textiles, laser welding guarantees lifetime and design consistency. Minimal heat-affected […]

Remove Oxidation and Trash from Jewelry surfaces

Laser cleaning in jewelry is used to remove oxidation and trash from metal surfaces thereby restoring their inherent shine without damage. With this method, gemstones may also be cleaned; it helps to eliminate impurities and enhance their clarity. Laser cleaning is used in fashion to eliminate stains and blemishes from delicate fabrics thereby maintaining their […]

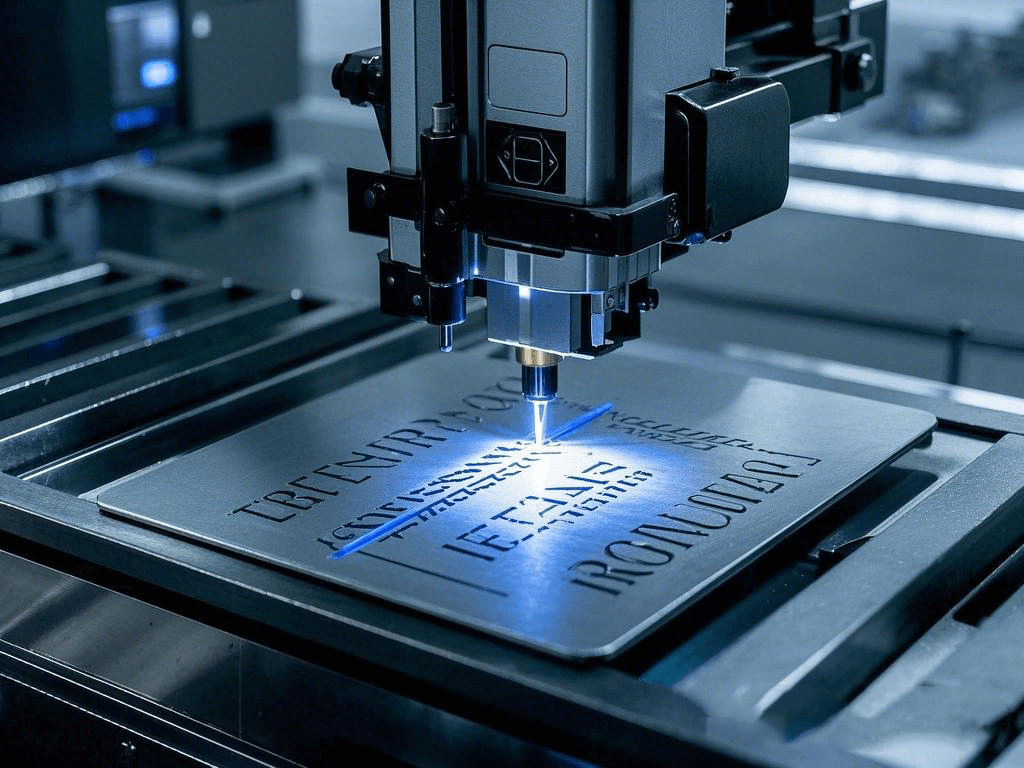

Laser Mark Design Patterns and Characters on Jewelry

Laser marking is a transforming tool with accuracy and customizing in the jewelry and fashion sectors. Mostly found in jewelry, engraving customized inscriptions and complex designs on items like rings, necklaces, and watches is done on By precisely stamping highly exact brands, initials, and even images, this method enhances the visual appeal and originality of […]

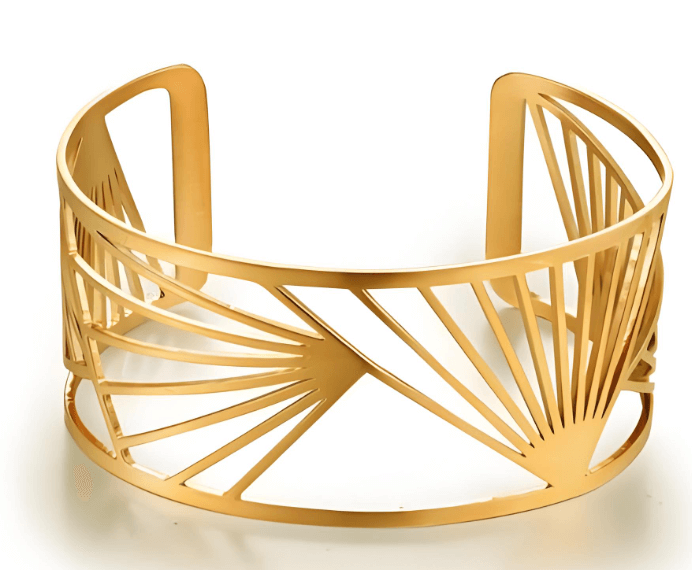

Cut Motif on Metal, Glass, and Crystal

Laser Cutting is a developing technique with accuracy and creativity promised. In jewelry, it is used to make complex motifs in metals such gold, silver, and platinum, therefore allowing beautiful patterns and unusual objects before difficult to obtain. Moreover improving the range of materials utilized in jewelry design is the cutting capacity of non-metal materials […]

Weld Robust and Neat Furniture Connection

Because of its accuracy, efficiency, and capacity to handle many materials with low thermal distortion, laser welding has grown to be a useful technique in the furniture and wooden products sectors. Laser welding is frequently used in the furniture industry to create strong, flawless connections between metal components including steel frames, hinges, and brackets with […]

Mark Brand, Pattern Decoration, Product ID for Furnitures

Both practical and decorative uses for laser marking are somewhat extensive. Whether furniture components are made of wood, metal, or another material, the accuracy and versatility of laser technology let producers create complex designs, logos, and patterns on them. Engraving logos, product information, and serial numbers for identification in branding and labelling. Creating distinctive patterns […]

Cut Panel, Legs, Metal Braces, etc For Furniture Products

For its accuracy, adaptability, and capacity to create complex designs on a range of materials, laser cutting is increasingly used in the furniture and wooden products sector. It helps producers to reach high degrees of detail that would be challenging or unattainable with conventional cutting techniques, such complex carvings, curves, and exact geometric forms. Process: […]

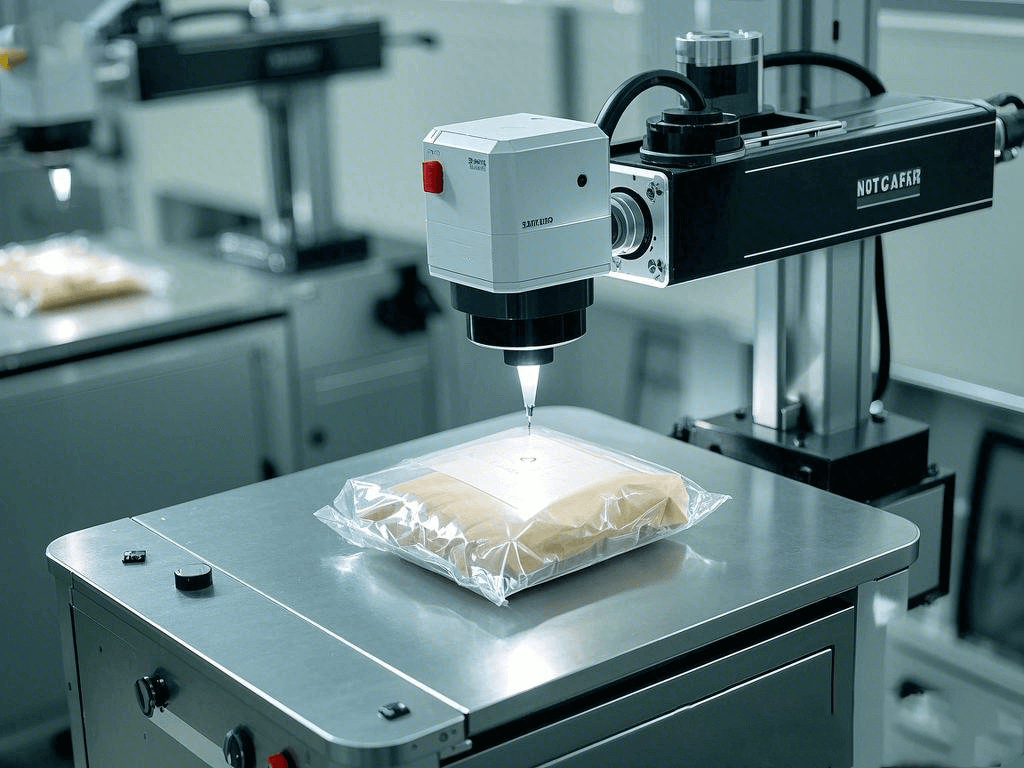

Laser Cut Package, Label, and Stickers

Cutting for a more individualized form and appearance. Creating useful, aesthetically pleasing, and safe food packaging depends on cutting, which also lets one better customize, use easier, and comply with hygienic regulations. To accommodate various products, packaging materials including cardboard, pouches, and plastic films must be cut to particular sizes. Perfect measurements made possible by […]

Expiration Date, Batch Codes and Logos Marking on Plastic, Glass, Metal

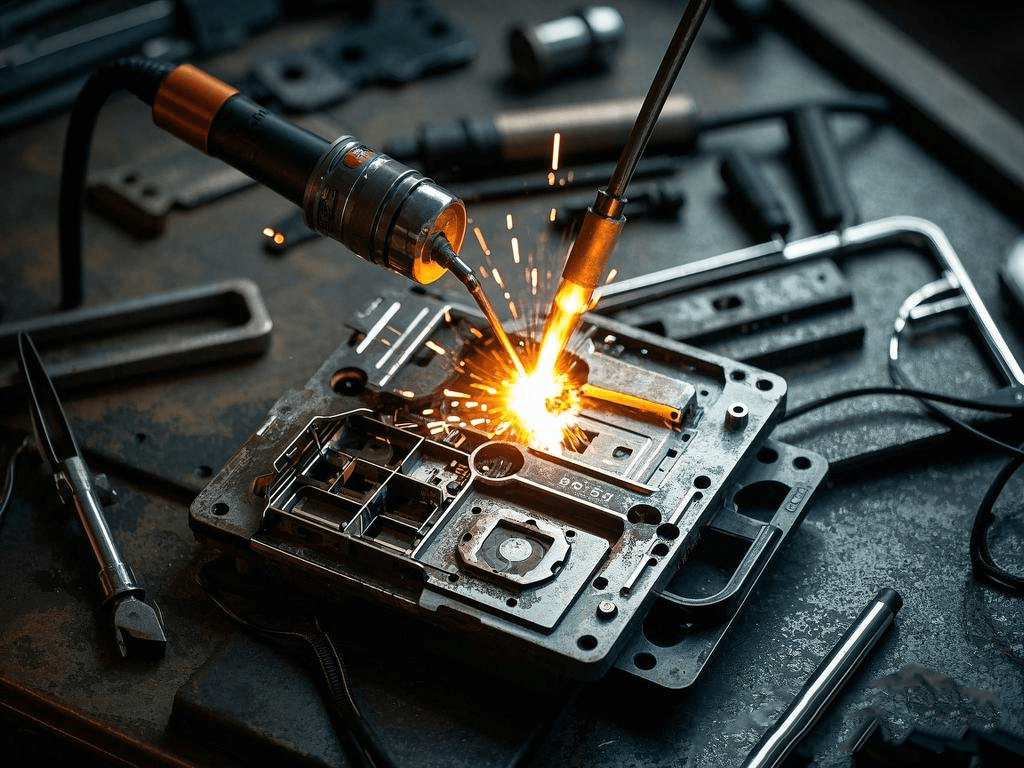

Weld delicate Parts and Outer Casing of Electronics

The electronics sector uses laser welding extensively to connect parts like circuit boards, batteries, and casings in devices such laptops and smartphones. Small, fragile parts would find it perfect for its accuracy, speed, and ability to produce strong, clean welds free from extra materials. Common application: 1. Smartphone and LaptopWithout compromising delicate parts, it provides […]