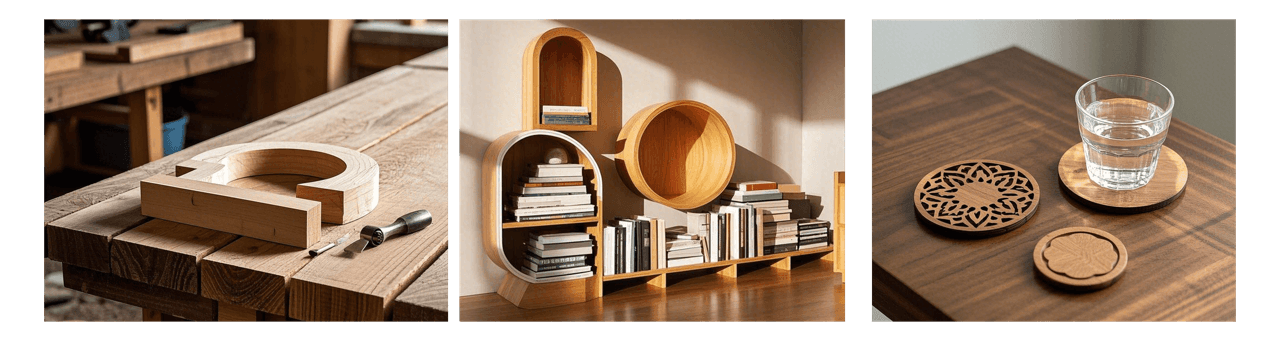

For its accuracy, adaptability, and capacity to create complex designs on a range of materials, laser cutting is increasingly used in the furniture and wooden products sector. It helps producers to reach high degrees of detail that would be challenging or unattainable with conventional cutting techniques, such complex carvings, curves, and exact geometric forms.

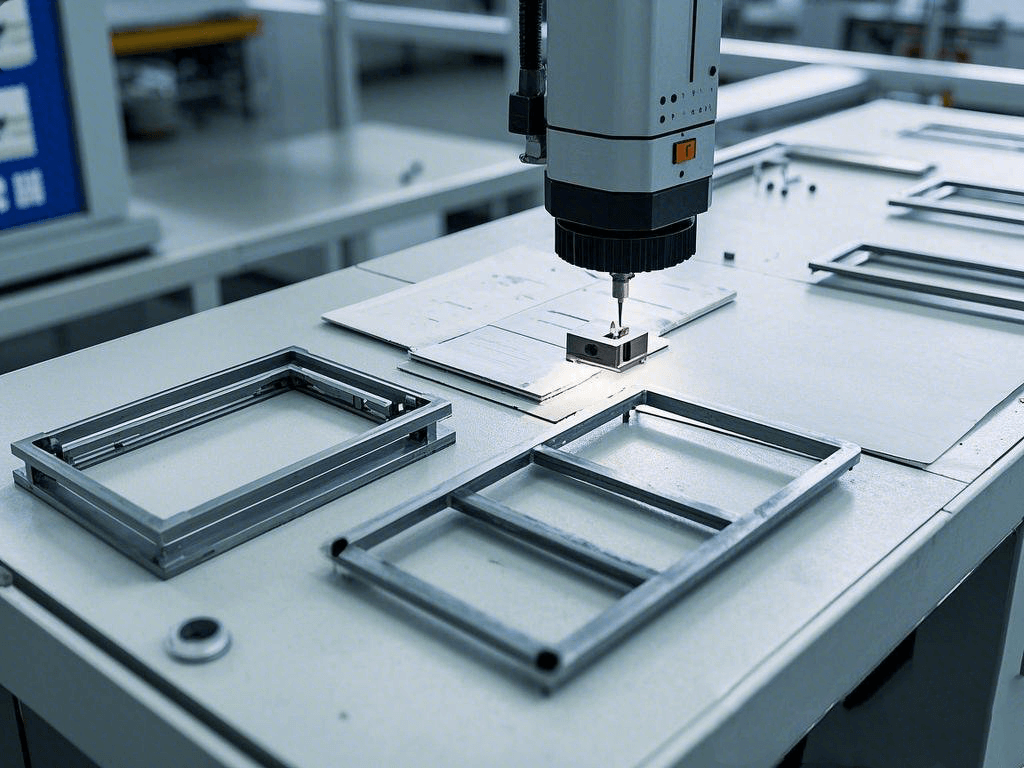

Process:

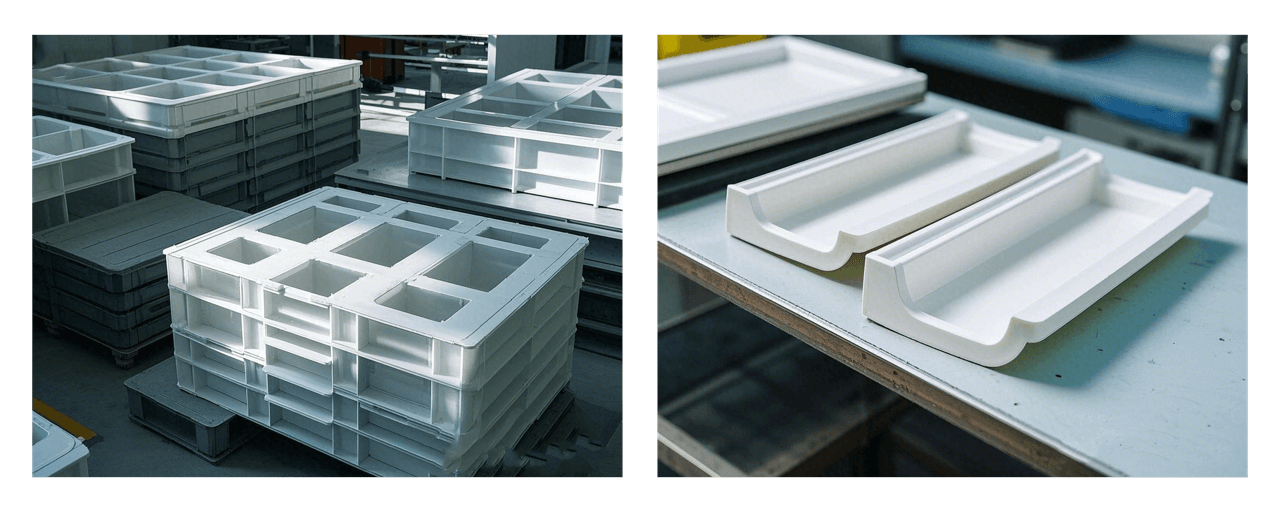

1. Cut raw materials into the required sizes by laser cutting, such as panels, legs, shelves, or supports.

2. Assembled these elements. Sometimes extra strength is given by metal braces or reinforcements.

3. To guarantee the pieces have a smooth surface and desired aesthetic look, the last stage consists in finishing touches like sanding, painting, stoning, or varnishing.

Benefit:

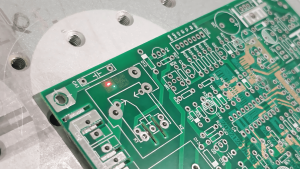

1. Excellent precision guarantees correct cuts for complex features and designs.

Cuts are clean, which lessens the requirement for post-processing based on smooth edges.

Maximizes material utilization, so reducing waste, so optimizing material efficiency.

Comparatively to conventional techniques, environmentally friendly technologies generate less waste, dust, and noise.