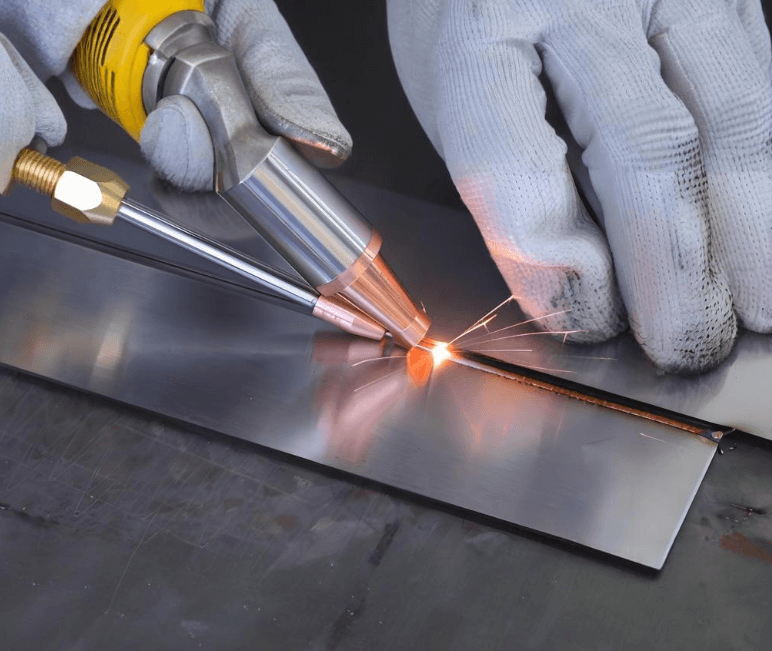

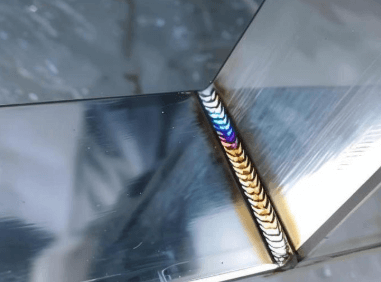

Precision and adaptability of laser welding contribute to explain its growing popularity in the tool and industrial sectors. It is widely used to combine tools and equipment parts to guarantee proper and strong bonding free from material distortion.

Its ideal for changing and fixing dies and molds to increase lifetime and save downtime is this technology. Reduced heat-affected zones and great accuracy of laser welding help to prevent damage to fragile parts.

Its non-contact approach fits premium manufacturing since it lowers wear and contamination risk. Additionally very compatible with automation is laser welding, therefore improving manufacturing process consistency and efficiency.