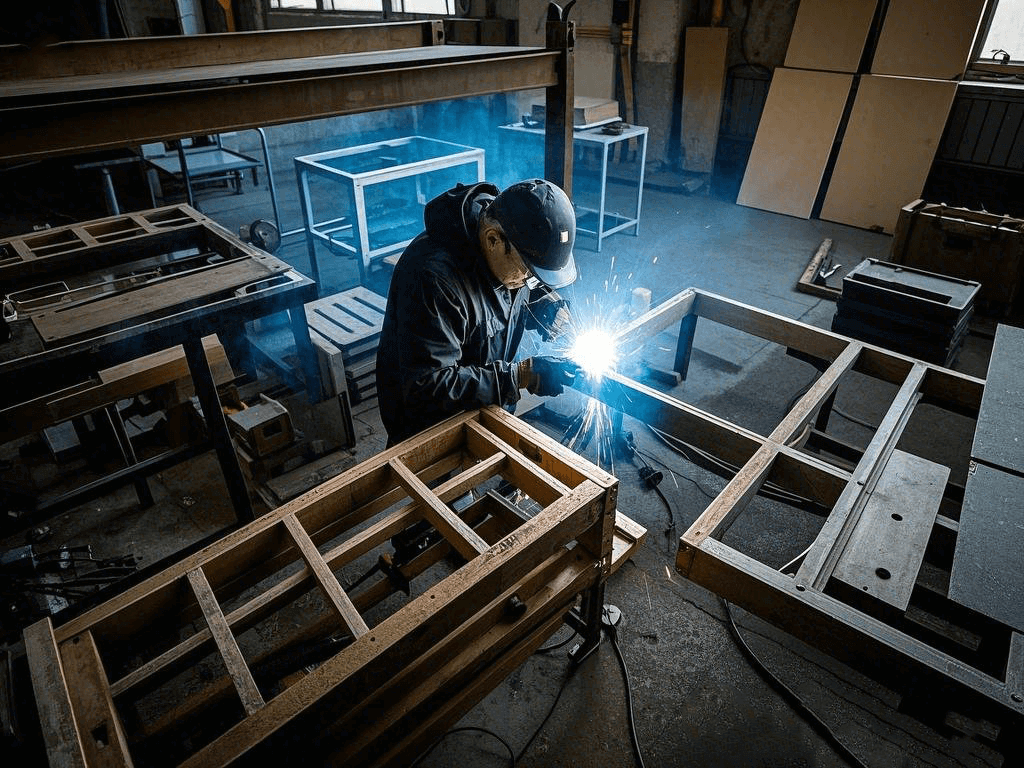

Because of its accuracy, efficiency, and capacity to handle many materials with low thermal distortion, laser welding has grown to be a useful technique in the furniture and wooden products sectors. Laser welding is frequently used in the furniture industry to create strong, flawless connections between metal components including steel frames, hinges, and brackets with hardwood elements without the requirement of bolts or screws.

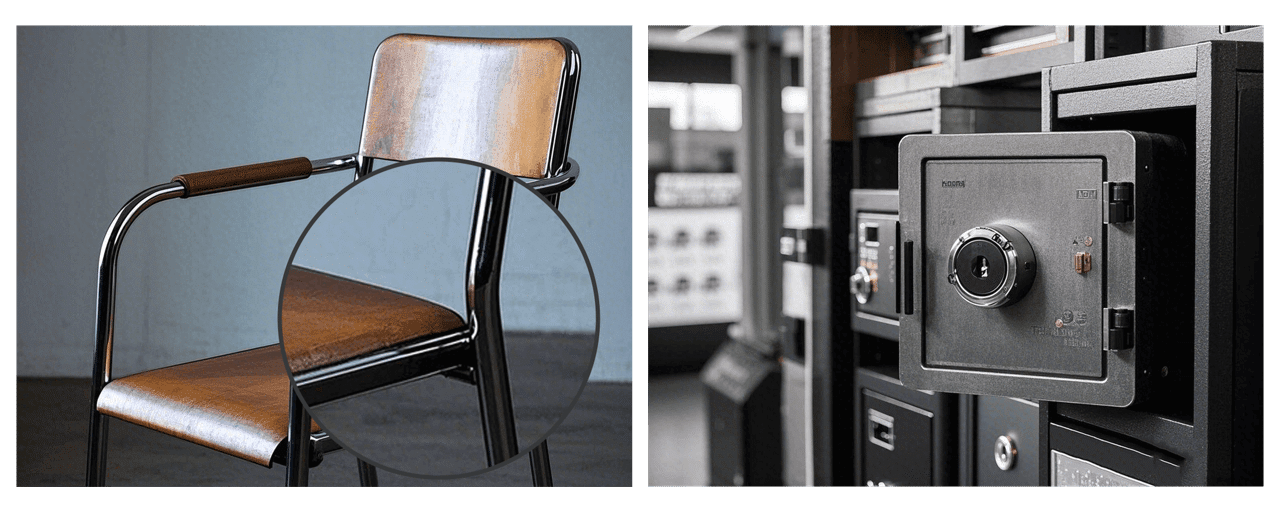

1. Welding for Furniture Connection and Fixing

Particularly for metal and composite furniture, laser welding is widely employed in the furniture sector to create robust, long-lasting bonds between several portions of the structure, including frames, legs, supports, and furniture component parts.

Highly exact welds made possible by laser welding guarantee clean, strong joins.

Particularly crucial in fragile or thin components, laser welding produces a limited heat-affected zone, therefore lowering the danger of warping or material damage.

Particularly for metal and composite furniture, laser welding is widely employed in the furniture sector to create robust, long-lasting bonds between several portions of the structure, including frames, legs, supports, and furniture component parts.

2. Welding for Perfect and Neat Look

Laser welding is the recommended method for obtaining neat, smooth, and aesthetically pleasing welds on furniture surfaces since visible weld marks or rough joints are unacceptable.

Laser welding reduces deformation or discolouration, thereby preserving a perfect and homogeneous surface that accentuates the visual attractiveness.

Subtle and strong design aspects can be obtained by means of laser welding, so enabling producers to produce highly visually appealing sophisticated and detailed metalwork.