The key reasons laser welding is chosen are its ability to generate high-quality, strong welds with low heat input, which reduces the danger of distortion or damage to delicate materials.

Advantages:

1. Minimal Heat Distortion

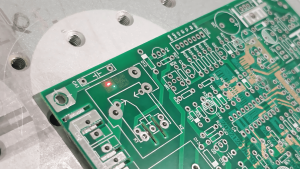

Laser welding adapt to aluminum or thin stainless steel, which are sensitive to heat, preventing distortion and guaranteeing the welded seams keep their original shape and strength.

2. Precision and Clean Welds

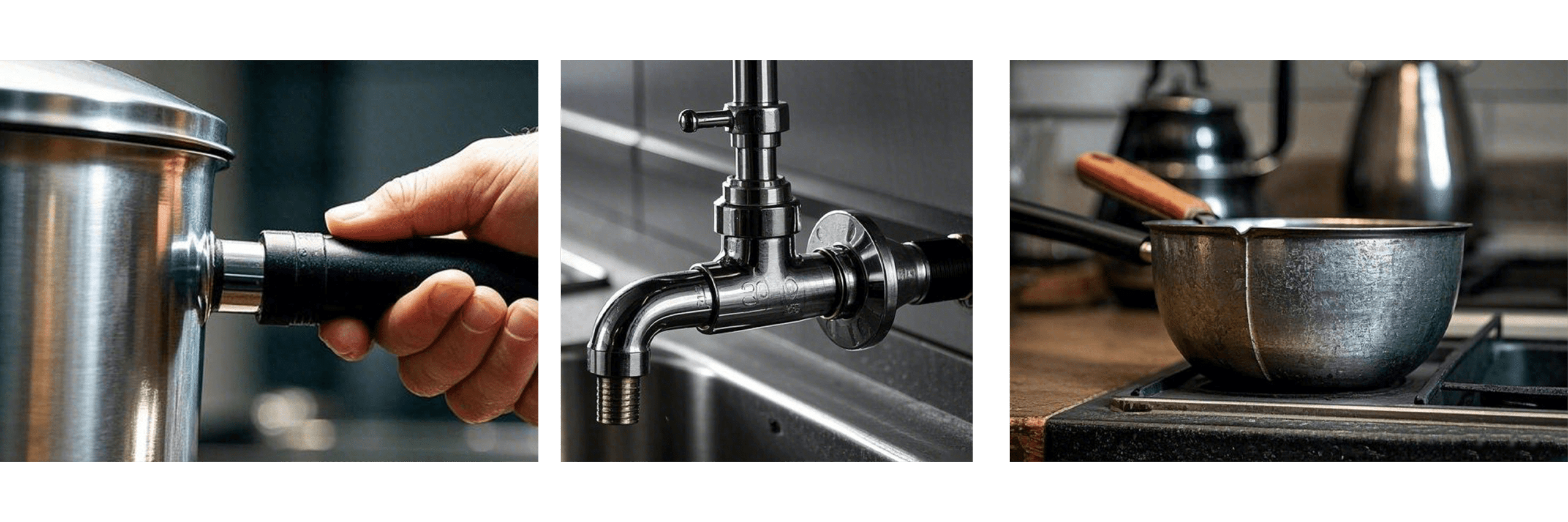

Laser welding excels in joining thin metal parts that are ubiquitous in home appliances.It ensures the product is beautiful, wear-resistant and long-term useful

3. Enhanced product safty

Consumer Goods have a wide range of application scenarios. Laser-welded items can be utilized in a variety of temperature conditions to assure safty.