Laser welding precisely and fast meets the particular requirements of these technologies from improving the structural integrity of wind turbine gears to guaranteeing the lifetime of solar panel connections.

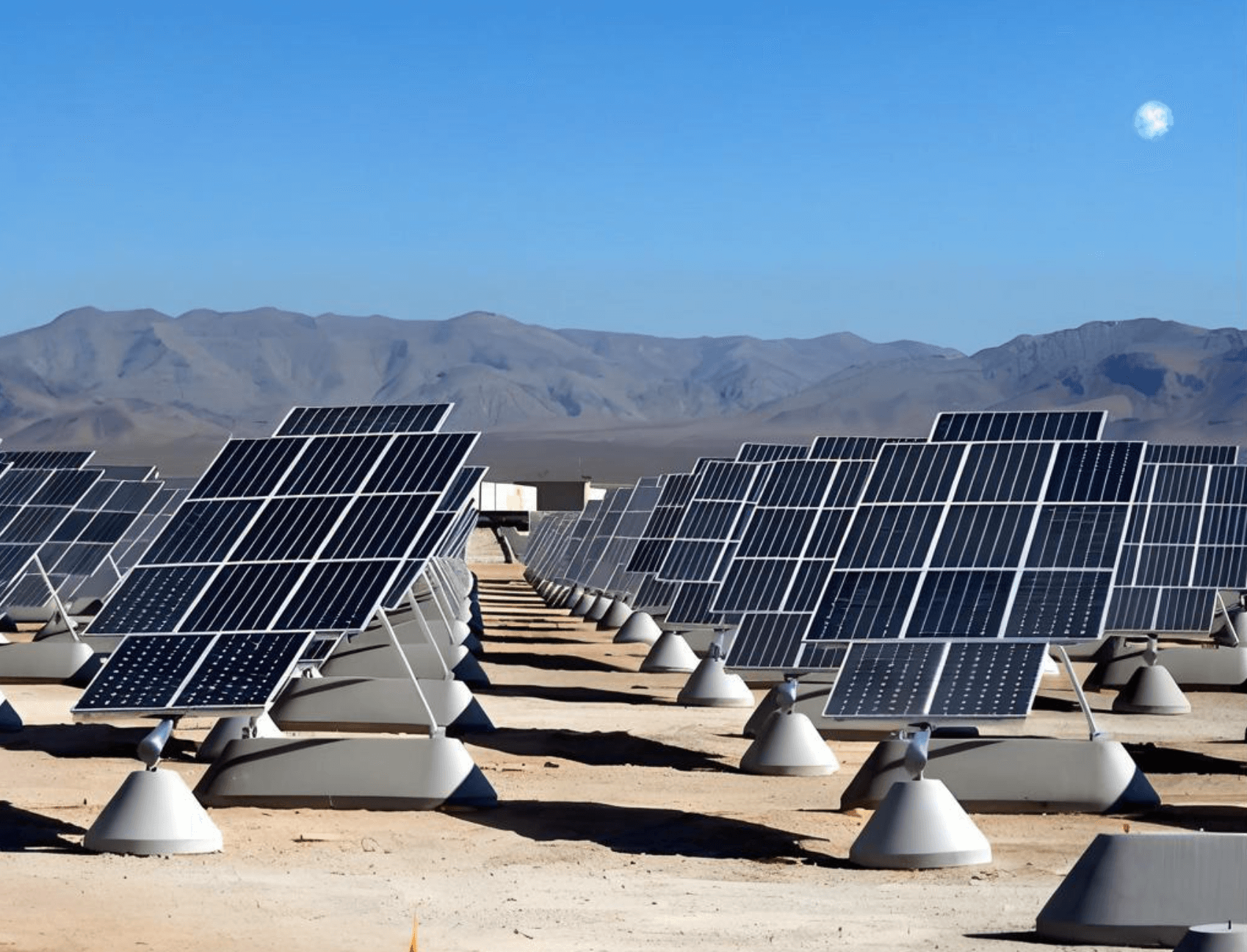

1.Solar Panel

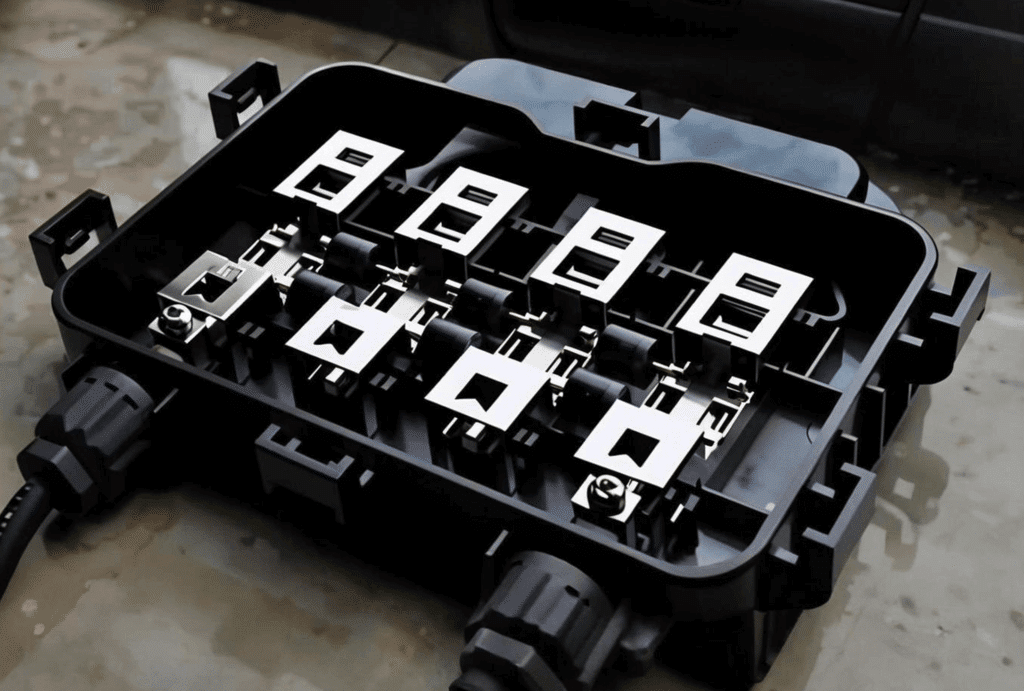

Solar panels’ metal components—including frames, junction boxes, and connectors—are joined using laser welding. It guarantees robust, exact welding without compromising the delicate cells, therefore improving the panel’s electrical conductivity and endurance.

Laser welding aluminum frames and electrical connections seals them, therefore shielding the panel from outside influences.

Precision welding produces dependable low-resistance electrical connections.

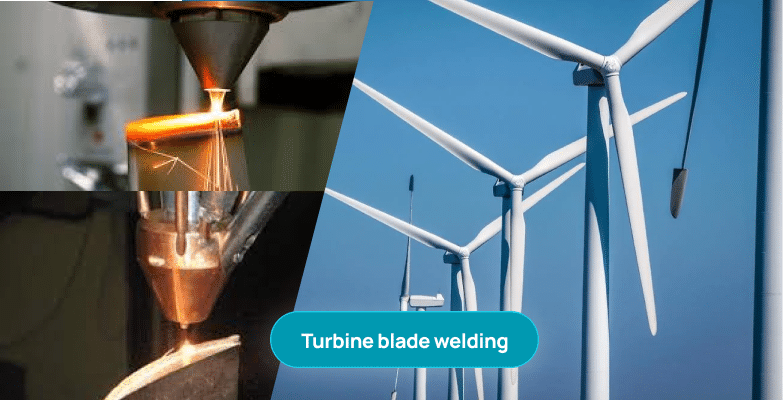

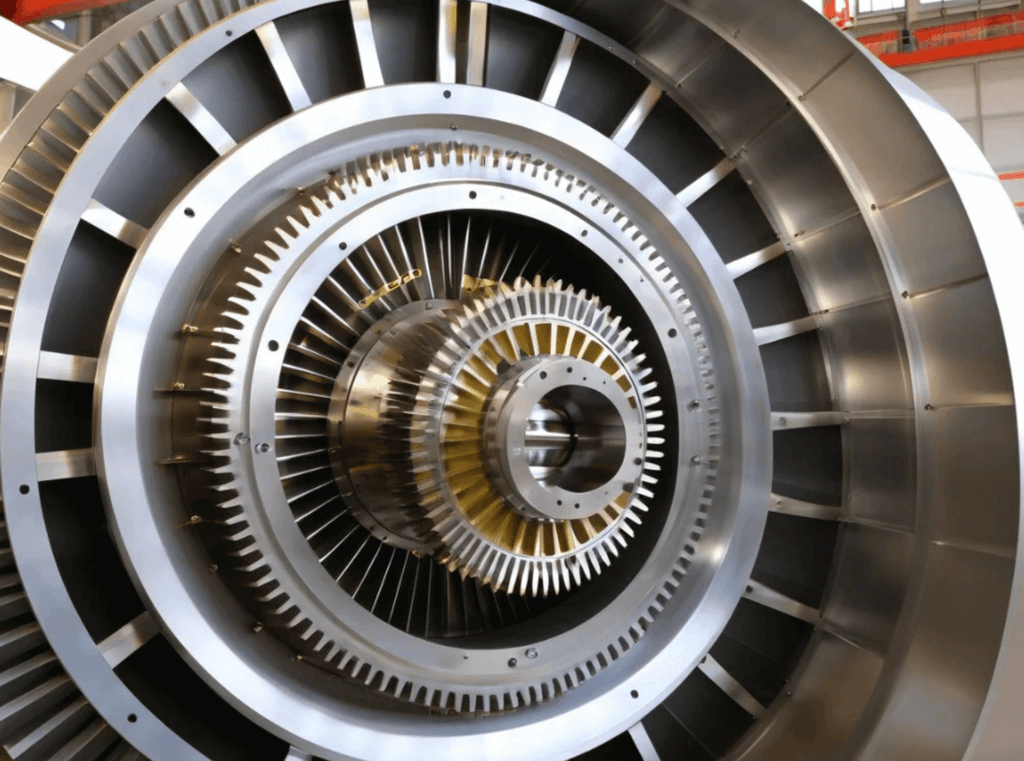

2. Wind Turbines

Especially for rotor blades, towers, and gearboxes, wind turbine construction depends on laser welding. It lowers component weight and stress while yet producing robust, long-lasting welds.

Welding sections of rotor blades guarantees strength and aerodynamic efficiency.

High-strength connections provided by laser welding enable reliable, long-lasting turbine construction.