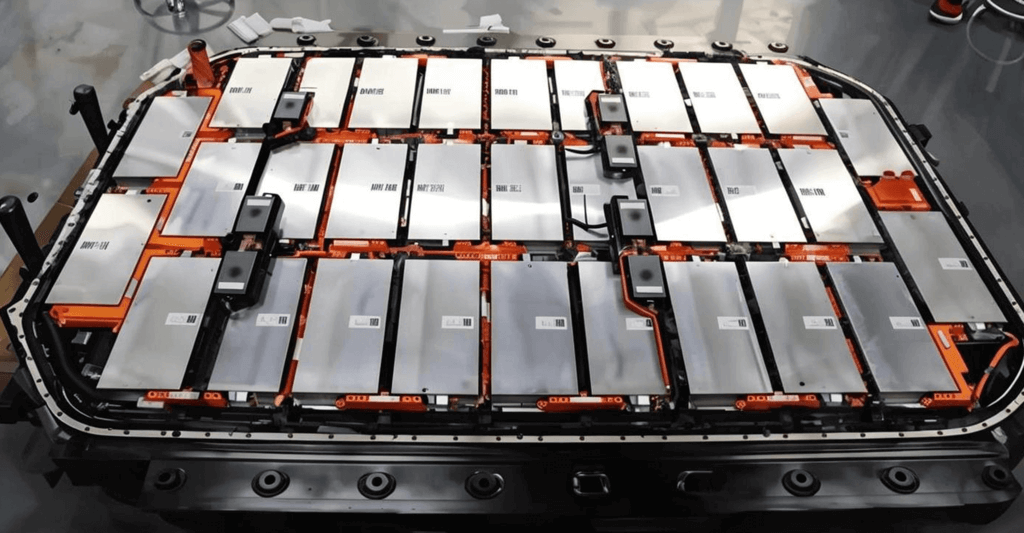

EVs and other energy storage devices need new energy battery packs. Their design and function impact battery pack safety and efficiency. In the construction of new energy battery packs, welding technology is crucial for joining battery cells and attaching the outside casing to interior components.

Welding in New Energy Battery Packs

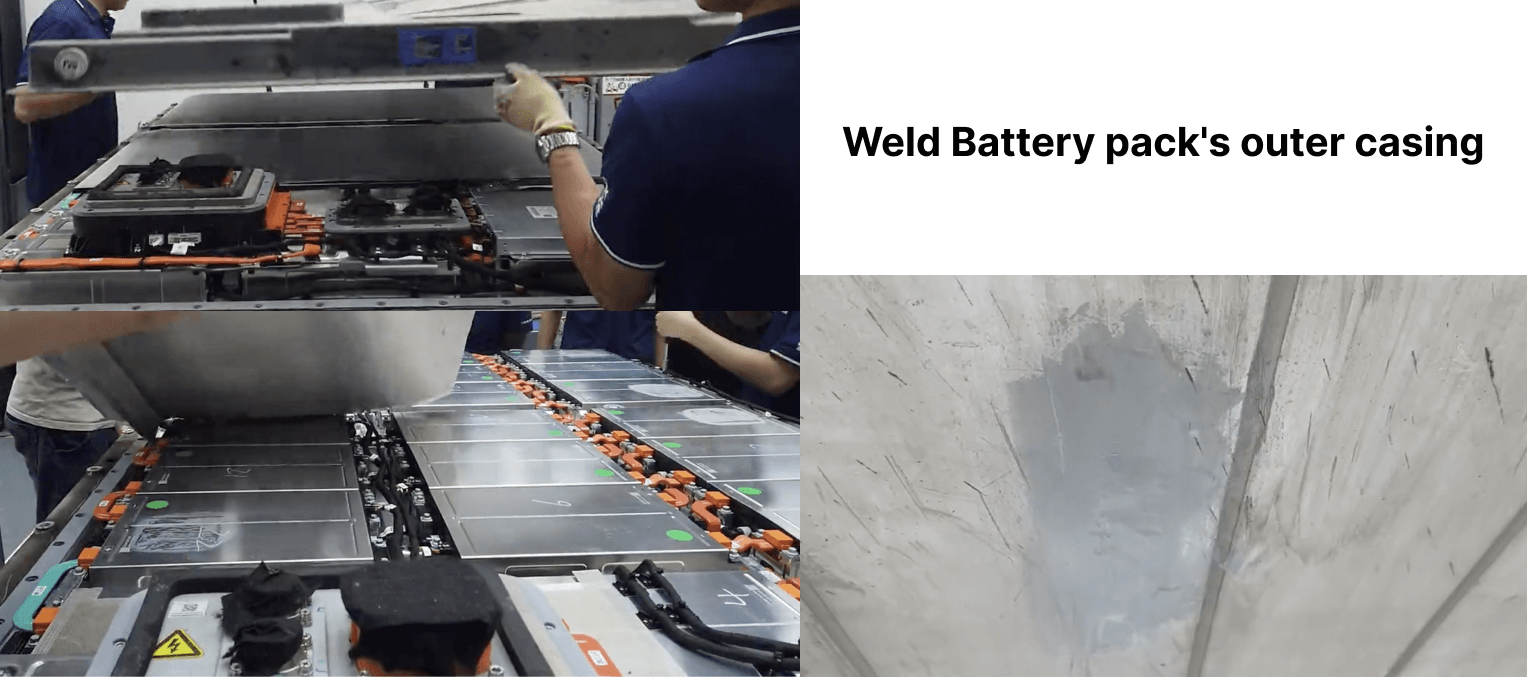

1. Welding is primarily used to join battery plates and series plates and assemble the battery pack’s housing. Standard welding procedures include spot welding, aluminum welding, and laser welding.

2. Laser welding is perfect for joining battery pack internals, especially battery cell connections, due to its speed, precision, and low heat-affected zone. Laser welding improves electrical conductivity, sealing, and strength.

3. Spot welding is used to attach battery pack metal plates. It bonds battery cells fast and reliably. Spot welding is ideal for mass production, but temperature and time must be controlled to avoid battery damage.

4. Aluminum welding: The battery pack’s outer casing is commonly made of aluminum welding due to its lightweight and corrosion-resistant qualities. This procedure requires specific aluminum welding equipment.

Our customers choose the equipment that suits them best from the following products:

- Circular Pneumatic Marking Machine

Key Welding Process Considerations Heat Management:

– Batteries create heat throughout charge and discharge cycles, requiring special attention during welding. Too much welding heat can cause battery overheating, internal short circuits, and structural damage, so control it.

– Safety and performance of the battery pack depend on weld quality. Welds must have high electrical conductivity, mechanical strength, and sealing to prevent welding errors from causing battery failures.

– Material Compatibility: New energy battery packs use copper, aluminum, and stainless steel, thus welding must consider material compatibility. To create secure, defect-free connections, different materials may require different welding procedures and settings.