Different parts in the electronics sector need laser marking for a different use. Particularly with small and complex items, laser marking is used for its accuracy, speed, and durability.

Laser marking technology finds extensive application in three primary forms of components in the electronics sector:

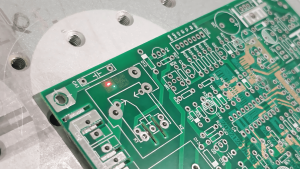

1. Electronic components—such as manufacturer emblems, batch numbers, date codes, and product numbers—need highly exact identification.

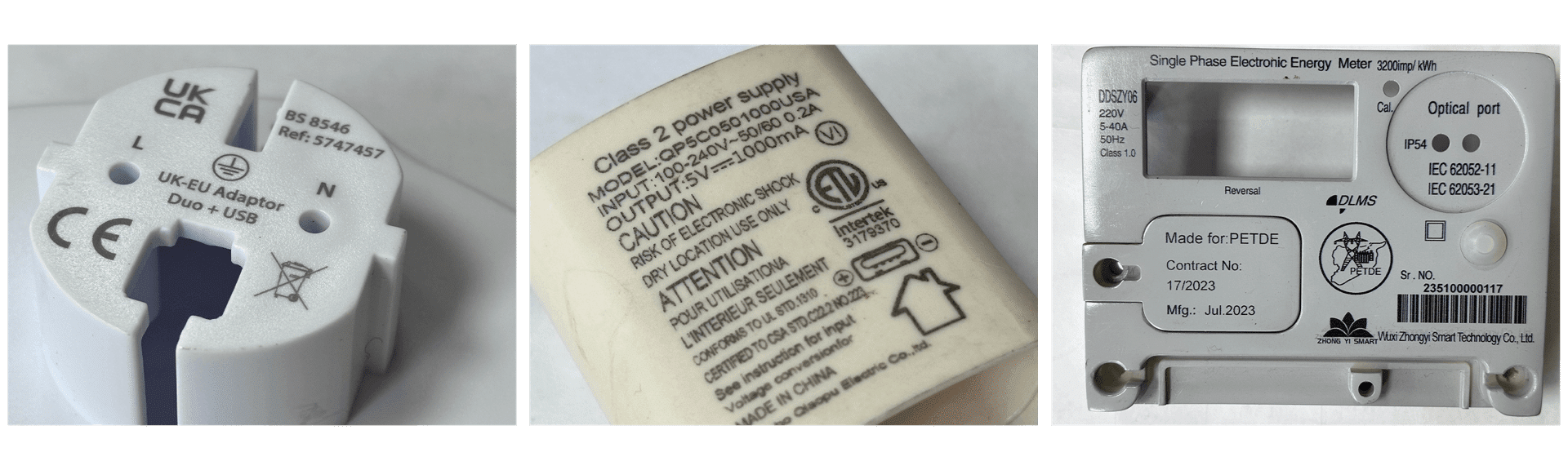

2. Casings and accessories—need to be marked with barcodes, QR codes, safety certifications, product information, and brand logos.

3. Connectors and cables—Laser marking can mark these information including identification, specifications, batch numbers, etc. to enable installation, repair and product traceability, therefore guaranteeing correct connection and quick identification during later maintenance.

Why laser marking is neccessary in electronics?

1. It is absolutely important for traceability since it enables producers to rapidly spot any flaws and track items from manufacture to end-use.

2. It enhances brand recognition by allowing the application of trademarks and logos, therefore supporting branding initiatives.

3. It facilitates part management during assembly, maintenance, or repairs, therefore helping with product identification.