Application of Laser Cleaning Machines in Shipbuilding and Ship Maintenance

Laser cleaning technology, utilizing high-power continuous fiber lasers integrated with

Sales Consultation

Post-Sales Support

Inguiry Form Submission

KT-UD

Suitable for high-demand customers

No thermal effect, no material burning

Low power consumption, stable performance

1. Food packaging materials

2.Pharmaceutical packaging materials

3.Glass materialsSilicon wafers

4.Precision plastics

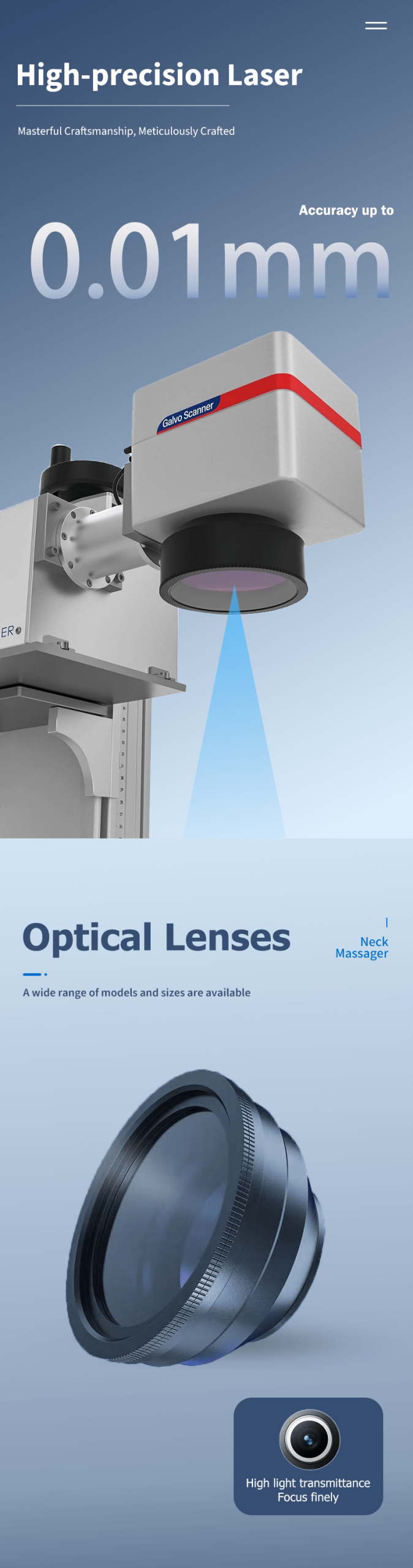

| Tagged speed | 6000mm/s |

| Positioning speed | 10000mm/s |

| recording speed | 510cps |

| Step response time (1% of full trip) | ≤0.08ms |

| zero drift | <25μRad/°C |

| input voltage | ±15VDC |

| Maximum average operating current | <1.5A |

| signal interface | 数字: XY2-100; 模拟: ±5V |

| working temperature | 25±20°C |

| Laser input aperture | 10mm |

| Mechanical scanning Angle | ±12.5° |

| system requirements | windows7,10,11 |

Suitable for marking on food and pharmaceutical packaging materials, high-speed division of glass materials, complex graphic cutting of silicon wafers, marking of electronic components and precision plastics.

Read our latest cases and guide to learn more about Kuntai Laser

Laser cleaning technology, utilizing high-power continuous fiber lasers integrated with

Laser welding and laser spot welding, with their advantages of

As demands for precision and traceability grow in PCB production,