Laser welding is perfect for the complicated and delicate components sometimes found in medical devices since it offers outstanding accuracy. By focusing the laser on small, detailed areas, producers can produce excellent welds on components with fine characteristics, such surgical tools, medical implants, and diagnostic equipment, or in close proximity to each other.

One non-contact technique that lowers the danger of contamination is laser welding. In the medical field, this is especially important since the addition of foreign particles or contaminants into the welding joint can threaten the sterility or safety of the device. Controlled settings allow laser welding to be carried out, therefore reducing the possible contamination risk.

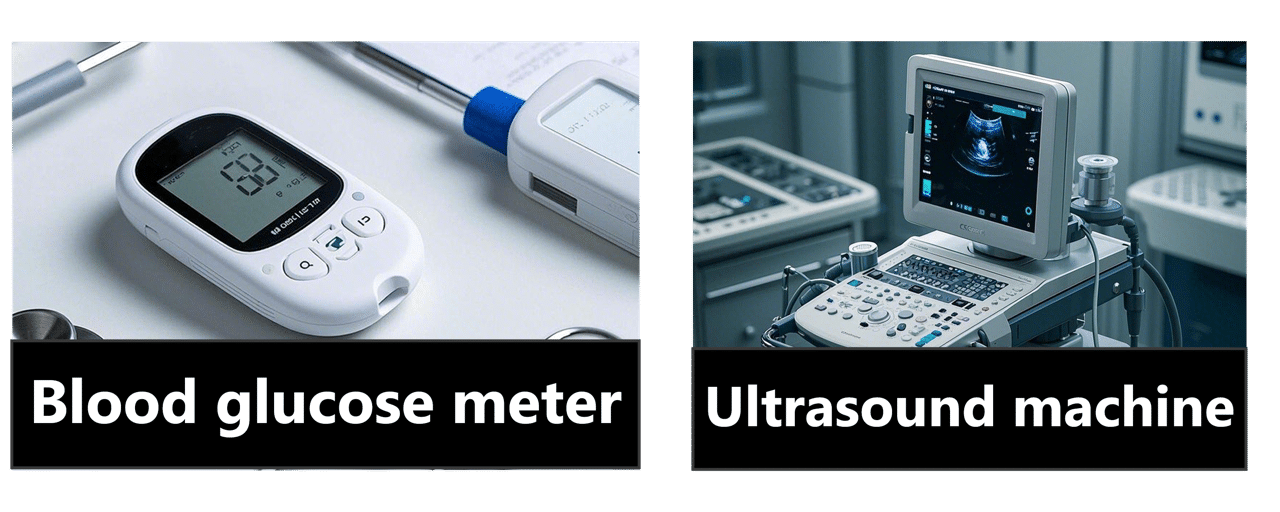

Diagnostic Equipment:

Laser welding guarantees the integrity of diagnostic equipment, which has to run consistently under a range of circumstances.

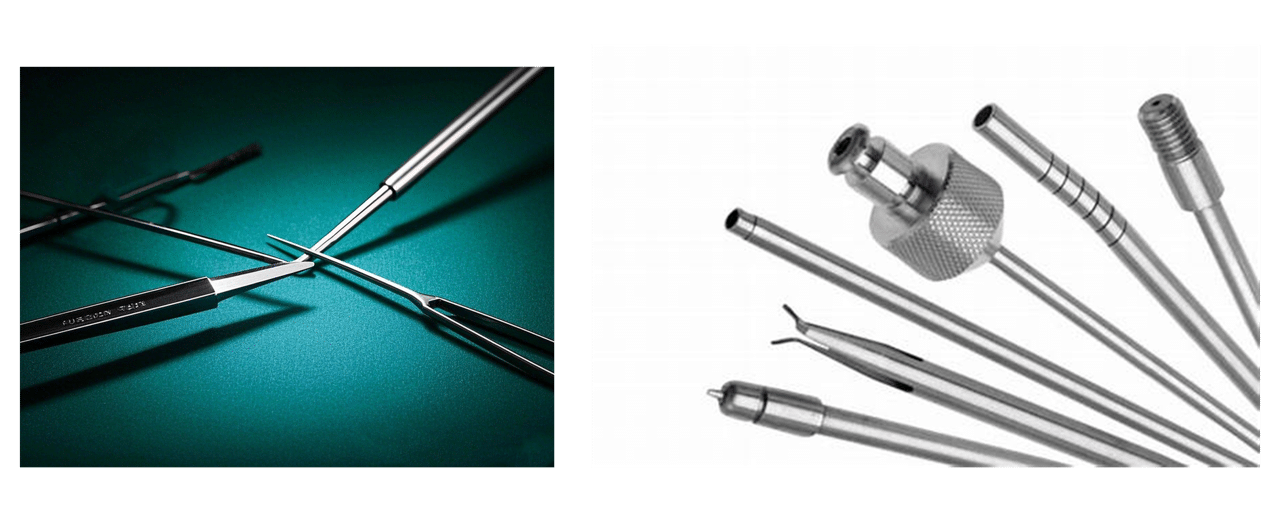

Surgical Instruments:

Precision welding of these small and complex instruments is used in surgery.

tidy, robust, and durable