Оглавление

How does the jewelry laser welding machine weld and repair jewelry?

Jewelry laser welding machines have become the hallmark of jewelry making, ushering precision and efficiency into the blueprints of both manufacturing and repair of fine jewelry. These machines utilize very intense light beams, outstandingly joining metal pieces with high precision targeted for delicate and intricate design work.

For example, resizing a ring, reattaching a gemstone setting, or repairing a broken chain would be performed without taking away from the integrity or the appearance of the jewelry. By low heat distortion, compatible with welding various metals, laser welding has established itself as an important modern machinery in making jewelry.

This article gives an overview of how jewelry laser welding machines operate, the extent to which they will process jewelry, their essential components, and the impact they have on jewelry quality and durability. Read till the end to understand how jewelry laser works.

Part 1: What is a jewelry laser welding machine?

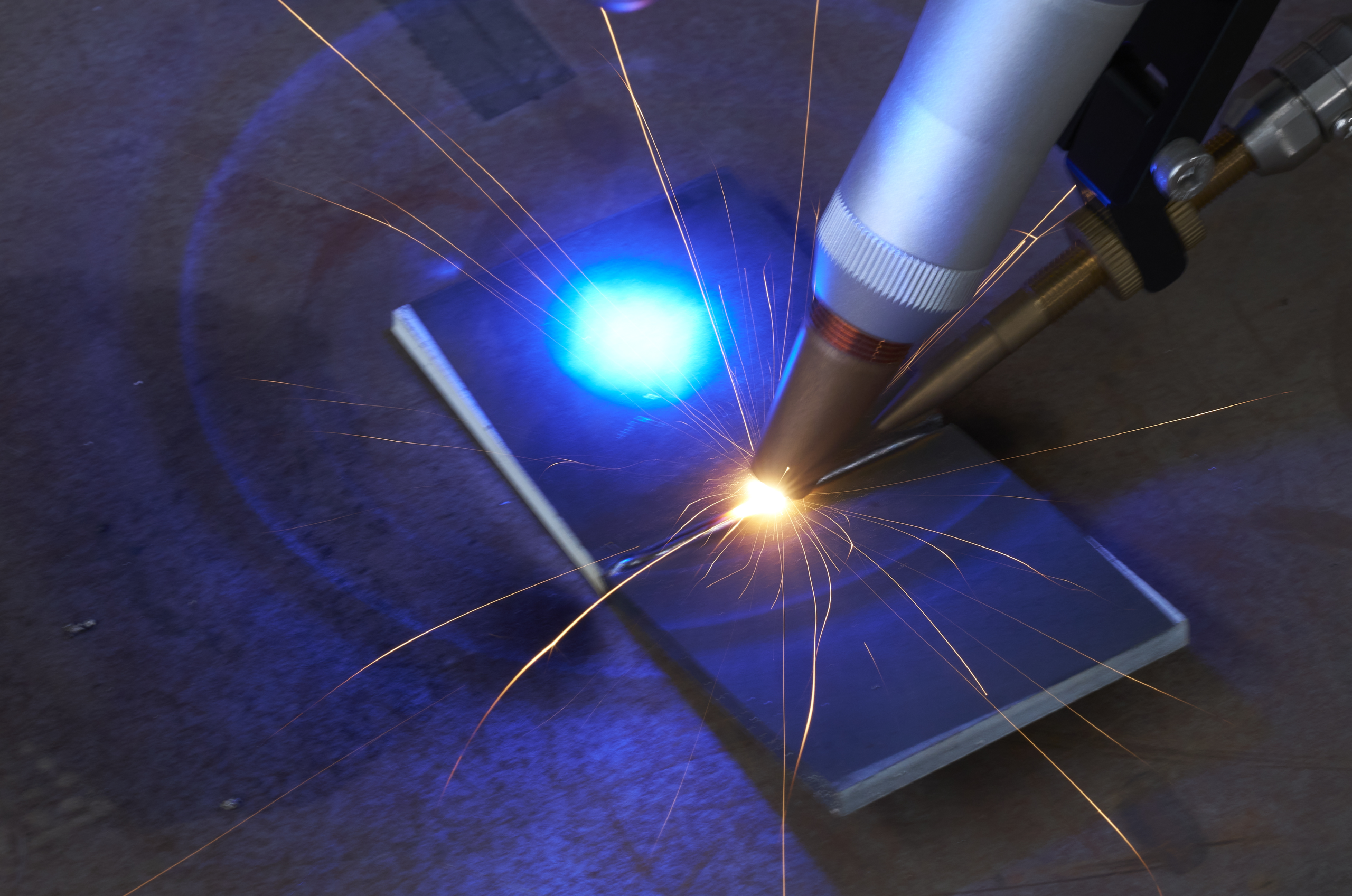

In the field of jewelry, a laser welding machine for jewelry acts as a unique weapon for the joining process of metal components with precision into a concentrated beam of light. This technique has replaced the traditional soldering with an open flame and filler material by processing metals by focused beam of light melting the two pieces together.

It creates strong, neat, and precise welds, completely unaffected by surrounding materials. Hence, this method is most suitable for delicate or very complex jewelry pieces. Using the Nd: YAG (Neodymium-doped Yttrium Aluminum Garnet) laser source affords these types of machines the ability to run high-energy pulses in extremely short bursts.

It can join small, highly intricate jewelry parts with the least heat effects. The specific focusing of laser energy assures that only the zone requiring welding is altered and that the surrounding material remains intact.

Excellent examples for welding fine metals are gold, silver, platinum, and titanium. Also, very efficient is welding with such an application on pieces of jewelry having heat-sensitive stones during repair.

In addition to welding, this machine offers options of repairing a crack in a piece, altering the size of a ring, linking broken chains, and providing very complicated custom designs thus providing unmatched precision in performance and efficiency in work to jewelers.

Part 2: What jewelry can be processed by a jewelry laser welding machine?

Jewelry laser Welding machine is one of the multipurpose machines in any jeweler’s workshop that can work on a range of jewelry and can weld many types of jewelry.

It can give highly localized heat treatments that can be useful in the precise processing of everything from very delicate rings for engagement to heavily gold-laden chains, without damage to adjacent components or heat-sensitive stones.

1. Rings

Common uses for laser welding machines include resizing of rings, filling cracks or breaks, and securing prongs around gemstones. Most of the ring remains unaffected due to embedded stones as a laser heats a tiny area.

2. Chains and Necklaces

Laser welding allows the seamless repair of broken chain links, clasps, and even delicate filigree designs. The precision and freedom associated with this machine permit line-by-line, microscopic alignment and joining of fine chains, which, otherwise, would have to suffer destruction by torching.

3. Earrings

The laser jewelry machine welds back posts, repairs damaged hooks, and reinforces clasps on stud and dangle earrings. With great precision, the laser provides a stronger and cleaner weld without changing the dimensions or shape of the earring.

4. Bracelets and Bangles

It allows a repair to be done on any crack, break, or looseness in settings on bracelets and bangles. Even some complex designs and combinations with other materials can also be adjusted in size or fit with efficiency.

5. Pendants and Charms

Pendants often have tiny joints or attaching spots that become useless over time. Laser welding permits the accurate joining of such parts whilst maintaining whatever intricate designs or gemstone settings were there.

Part 3: What are the components of a jewelry laser welding machine?

They include:

1. Laser Source (The Laser Generator)

The laser source is what the welding machine relies on. Most jewelry welders operate through a pulsed Nd: YAG laser, which emits high-energy bursts of light, shorn, in the near-infrared spectrum.

These pulses can be controlled for depth, duration, and frequency, and thus have enabled accurate welding of delicately formulated jewelry parts without causing the surrounding areas to be overheated. The quality and power of the laser source determine the capacity of the machine to weld different types and thicknesses of metals.

2. Optical System (Beam Delivery System)

An optical system consists of lenses and mirrors directing the laser beam to the target area. The quality of optics ensures the beam is sharp and concentrated, which is critical for making welds clean and precise.

3. Microscope or Viewing System

Jewelry laser welding machines are fitted with either a stereo microscope or a camera plus display to help view the work area better. This is very important in precision, especially in handling tiny or detailed jewelry.

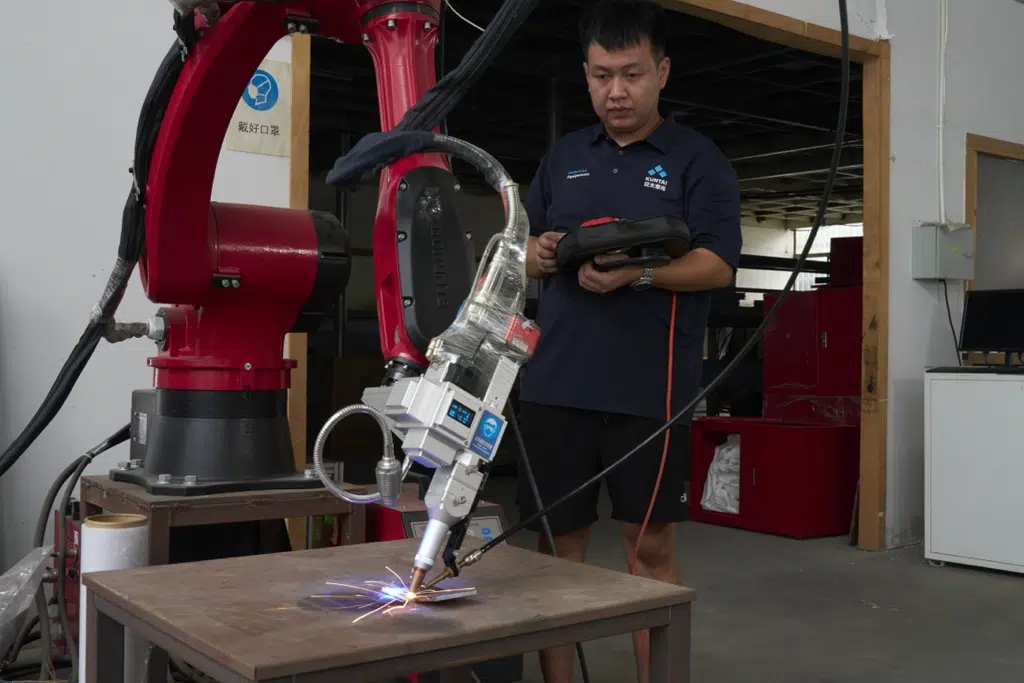

4. Control Panel (User Interface)

laser power, frequency, and focus. Present-day machines come with a touchscreen interface along with memory presets created for different welding scenarios, making the working environment efficient and pleasant.

5. Cooling System

The laser welding process generates heat, even during short pulses. A cooling system, either air cooling or water cooling, is embedded in the machine to avoid massive overheating. It holds the temperature of the laser source and other critical components, serving to ensure their performance, resulting in longer life for the machine.

6. Welding Chamber (Work Area)

This pertains to the area enclosed for the actual procedure of the welding process. Glove ports are provided through which the operator may manipulate the jewelry without compromising the environment. The clean and controlled environment may host an inert gas nozzle for argon or nitrogen release into the chamber to minimize weld oxidation and thus enhance quality.

Part 4: Does using a jewelry laser welding machine have any effect on jewelry?

There are very beneficial effects and a few negative effects on the jewelry due to some processing and materials from the use of a jewelry laser welding machine. When this technology offers some advantages in terms of precision and efficiency, it is also very important to know how laser welding affects quality, appearance, and integrity in metals.

Positive Effects

1. Minimal Heat Affected Zone (HAZ)

It is one great advantage of laser welding machines that they can deliver heat to a very localized area. Due to the very sharply focused beam of light, the welding takes place in the metal joining region, with no effect on material surrounding it.

This is very important in delicate and heat-sensitive pieces. It means that the piece is retained in integrity concerning shape and finish, with no warping or discoloration that may occur in the case of traditional soldering practices.

2. Preservation of Surface Finish of the Metal

The laser welding reduces the chances of tarnishing and discoloration of the jewelry. On the other hand, flame-welding or soldering tends to oxidize or transform any other metal adjoining the region that has been welded.

This is indeed the reason we consider laser welding to be highly useful for high-grade jewelry, which is meant to have its surface finish and polish intact based on appearance in fine gold, platinum, and silver.

3. Very strong, durable joints

By laser welding, one can join metals with the use of heat, which forms a molecular bond in one joint. Sometimes, the bond becomes stronger than even the original metal; therefore, the repairs are so joined that they are even stronger, and if not stronger than, the metal surrounding it. Thus, jewelry pieces become more solid and long-lasting.

Negative effects

1. Heat Sensitivity of Gemstones

Though the laser appropriately focuses on the area through which it passes, it cannot be said there is no risk at all when welding some stones, particularly softer or more heat-sensitive types such as opal, emerald, and pearl.

Gems mostly can stay in their positions during the welding process, but special precautions must be taken with particularly delicate stones- removing the stone prior to welding, for example.

2. Compatibility of the Filler Material

In this case, any filler added for the welding process has to match the specific base metal to maintain the aesthetic continuity.

Aligned fillings would give a seamless joint appearance without visible seams or discoloration in the joint, which would otherwise detract from the overall appearance of the jewelry.

Part 5. How does the jewelry laser welding machine weld jewelry?

Step-by-Step Welding Process:

- Workpiece Preparation: Before welding, the jeweler cleans and arranges the jewelry parts together, ensuring position accuracy. Any dirt, oil, or oxidation on the surfaces will result in poor quality of the weld.

- Machine Parameters: Using the machine control panel, the jeweler sets up the parameters of the laser. The adjustable settings lower the pulse energy, increase duration or number of cycles, and increase focus in a laser. All these vary based on the type of metal, the thickness of the metal, and the size of the required weld.

- Targeting Weld Location Using the inbuilt microscope or camera system, the jeweler meticulously aligns the laser beam to its exact weld area. It also has a reticle or crosshair, which gives the laser focal point, allowing extreme accuracy.

- Laser Activation:Once the jewelry is properly lined up, the jeweler activates the machine by foot pedal or trigger switch, which pulses within the machine to create a precisely timed light explosion that rapidly produces incandescence-heating and melting the metal exactly where it is required.

- Cooling and Finishing:On a normal basis for the metal portions used in jewelry making, due to its short laser pulse and concentrated heat following the weld, it cools off at a very rapid pace; this weld point can then be polished, smoothed, or finished that it is hard to tell the difference from the rest of the piece.

Part 6. How does the jewelry laser welding machine repair jewelry?

A jewelry laser welding machine repairs jewelry depending on the issue at hand. Let’s check some of the common repairs available.

Types of Most Common Jewelry Repairs

1. Cracked or Broken Metal Parts

Laser welding repairs cracks in rings, bracelets, or pendants by joining the broken ends. Concentrated heating using a laser melts metal only at sites of the crack, resulting in a clean, strong bond and restoring the integrity of the piece.

2. Restoring Pronged Pendants and Stone Settings

The prongs bearing stones may eventually be worn down, causing the loss of the stone. This process involves laser weld reconstruction without taking out the very stone that is prone to heat damage..

3. Ring Resizing and Shank Repair

The addition or subtraction of metallic mass during the resizing of rings is often handled by the welders. Such new materials are eventually smoothed and polished and seamlessly joined so that their join is difficult to recognize from the original ring.

4. Chain and Clasp Repairs

Broken clasps and delicate chain links can be repaired with quickness and accuracy. Rejoining small metal components that are difficult to fabricate can be achieved by using a laser.

Common steps to repair jewelry using a laser welding machine

- Inspect the jewelry to identify the damage.

- Clean the jewelry to remove dirt, oils, or oxidation.

- Secure the jewelry in the welding chamber or holder.

- Select and prepare matching filler wire (if needed).

- Adjust laser settings (power, pulse duration, frequency, etc.).

- Use the microscope or camera to align the weld area.

- Apply laser pulses to weld or rebuild the damaged area.

Conclusion

Jewelry laser welding machines have taken the novelty of designing and repairing fine pieces of jewelry to a different level entirely. They provide unmatched precision, speed, and safety.

The formula covers anything from rejoining broken chains, resizing rings, prong repair, to strong, clean welds that one could easily administer in providing safety for precious stones or intricate designs. In other words, by the use of a laser, welders could do an incredible job by working on anything with several metals without applying much heat to the piece.

Yet as technology continues, laser welding will have to become the primary tool of the modern jewelry workshop. It is investing in the future because it makes sense for the jeweler who wants to work more efficiently and craft the product better. The sure shot of high-quality results and satisfied customers.