This week, KUNTAI LASER had the honor of welcoming a distinguished customer from Sri Lanka — a manufacturer specializing in automotive components — to our headquarters and production facility. The visit was part of the client’s evaluation process to identify reliable and advanced laser equipment suppliers capable of supporting their growing production demands.

Overview of the Visit

The customer’s delegation included the company’s procurement manager and technical engineers. The primary objectives of the visit were:

- To understand KUNTAI LASER’s manufacturing capabilities and technical strengths

- To witness live demonstrations of laser equipment relevant to their production requirements

- To assess machine performance on-site using actual sample parts

- To discuss possible customization and post-sales technical support for overseas clients

We began the visit with a guided tour of our production workshop, assembly line, quality control area, and testing labs. Our team provided detailed introductions to our manufacturing standards, internal inspection procedures, and equipment calibration protocols.

The client showed particular interest in the following equipment:

- Fiber Laser Marking Machine: Demonstrated on various metallic parts, including automotive brackets and aluminum engine components. We performed tests with different marking depths, resolutions, and layout variations to simulate real production scenarios.

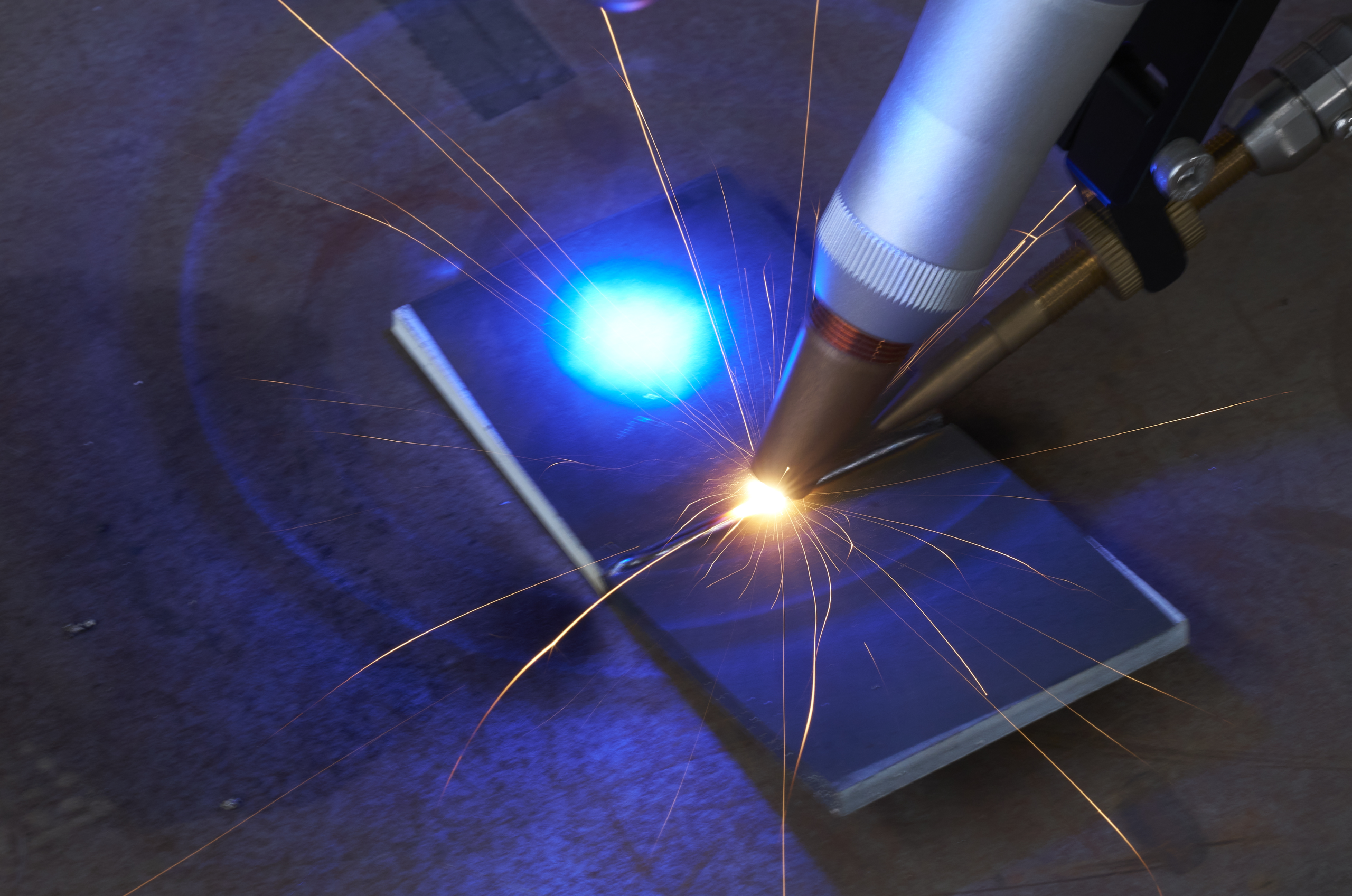

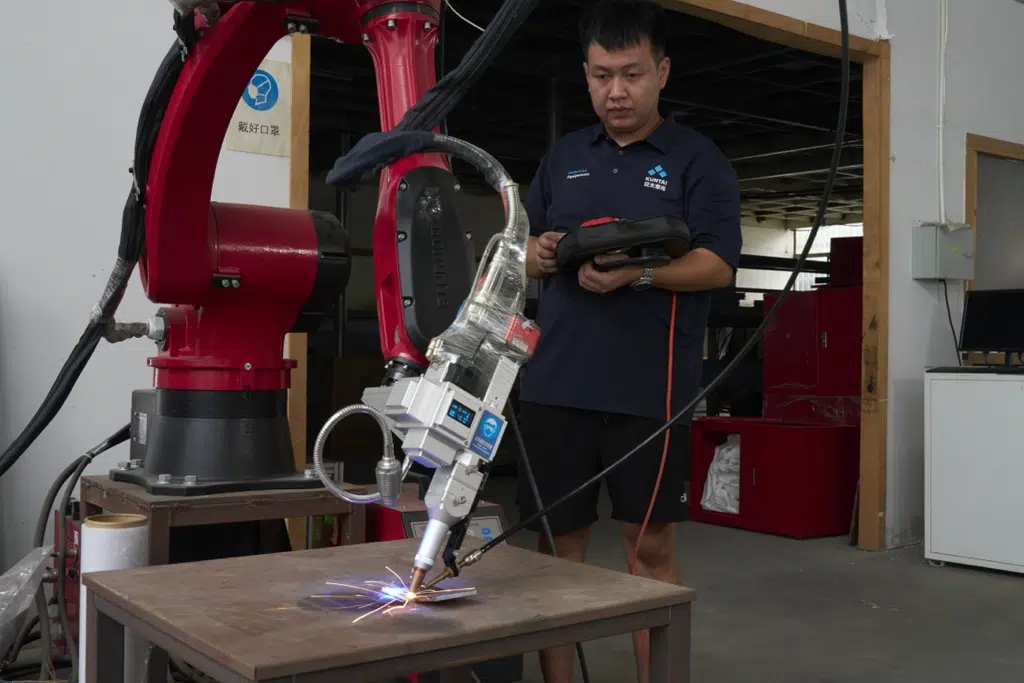

- Laser Welding Machine: Focused on precision welding of small stainless steel and aluminum parts. Our engineers showcased welding on sample joint structures similar to those used in sensor brackets and automotive connectors.

- Laser Cleaning System: Briefly introduced for potential use in rust removal and surface preparation of metal parts before assembly or coating.

All testing was done using the customer’s own samples, which they had brought along for performance evaluation. The customer expressed satisfaction with the marking clarity, welding seam consistency, and machine stability during repeated operations.

We deeply appreciate the trust placed in KUNTAI LASER and the opportunity to demonstrate our commitment to quality, innovation, and customer service. We look forward to building a long-term partnership and supporting the customer’s manufacturing goals in Sri Lanka and beyond.