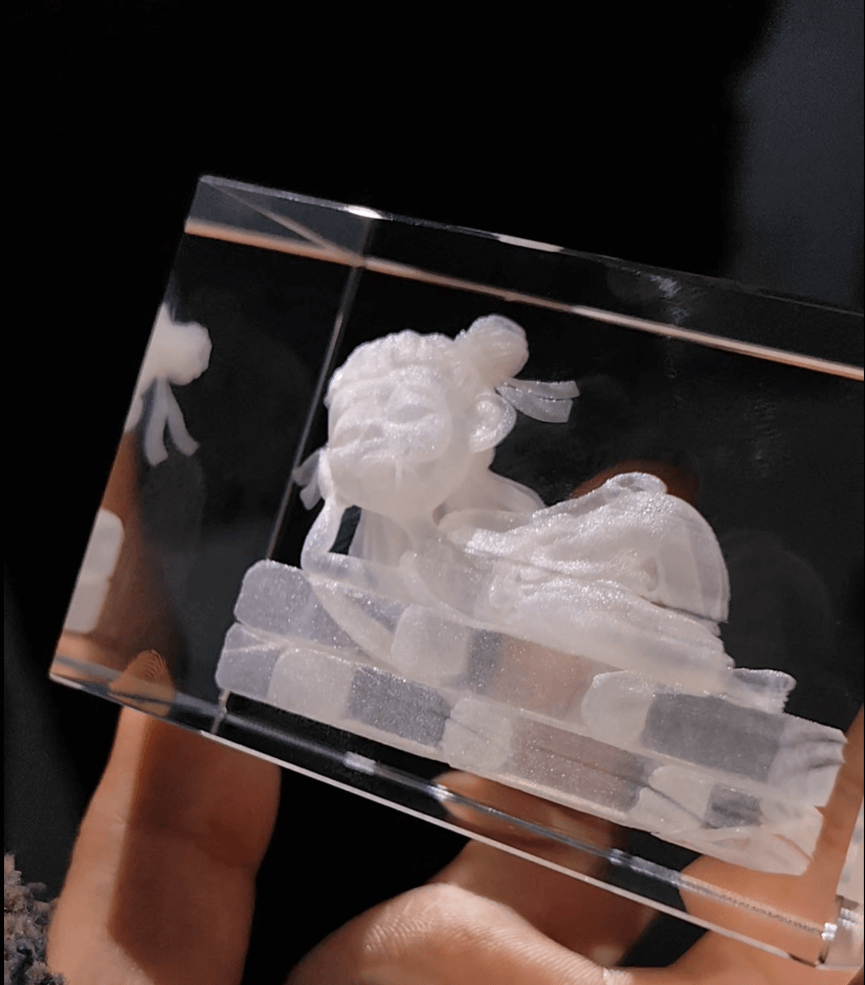

ローマ人は「クリスタルレーザー」を使って火を灯し、クンタイ人は星を彫るのにそれを使う

In 50 BC, a mysterious arson occurred in the Roman Senate. Historians found clues in the fragments: At that time, nobles were popular with “fire crystals” to focus sunlight to ignite the sacred fire. A piece of pure Roman crystal could ignite olive oil in 30 seconds under the midday sun – this may be the world’s earliest “optical weapon”. Crystal engraving: the magic of light and shadow The principle of crystal engraving is actually a wonderful encounter between light and matter. It uses special laser technology. The laser of a certain wavelength is shot into the crystal causes tiny bursts in specific areas of the interior to form bubbles. This will […]

中国顧客 | 2025年3月、キーエンス検出システムによる統合マーキング

Kuntai Laser presents a customized automated laser marking machine designed and manufactured for a Chinese client, specifically for batch marking of copper sleeve components. The machine operates under computer control, ensuring high efficiency and precision in laser engraving. To further enhance quality assurance, we have integrated a Keyence detection system at the end of the production line. This system automatically inspects the markings on the copper sleeves. If the marking meets the required clarity and accuracy, the system displays a green indicator light. If the marking is defective, a red indicator light is shown, allowing operators to quickly identify and locate the specific non-compliant component. In addition to our standard […]

クンタイレーザーが第10回上海国際工作機械展示会に参加

Yesterday, Kuntai Laser visited the 10th Shanghai International Machine Tool Exhibition, which showcased significant advancements in parts processing and the latest specialized machine tools. Prominent exhibitors included Yamazaki Mazak and Hyundai Wia, displaying cutting-edge equipment for new energy vehicle components, while Tsugami and Citizen showcased high-end lathes and machining centers for electronics manufacturing. Okuma and Genesis presented advanced aerospace processing technologies. A special highlight of the exhibition was the “Belt and Road” Industrial Mother Machine International Forum, where representatives from over 30 countries engaged in discussions on cross-national cooperation and strategies for global market expansion.

ブラジルの顧客 | 2025年3月、ドア用ワイドフォーマットレーザーマーキングマシンを探す

Recently, a valued client from Brazil visited Kuntai Laser’s factory to witness the impressive capabilities of our large-format marking machines. During the visit, the client observed a live demonstration of intricate pattern engraving on doors and windows, showcasing the precision and efficiency of our equipment. Our sales colleague, Tracy, provided a detailed introduction to the machine’s advanced features, including its high-speed engraving, customizable designs, and user-friendly operation. The client expressed great interest in the technology and its potential applications in their manufacturing processes.

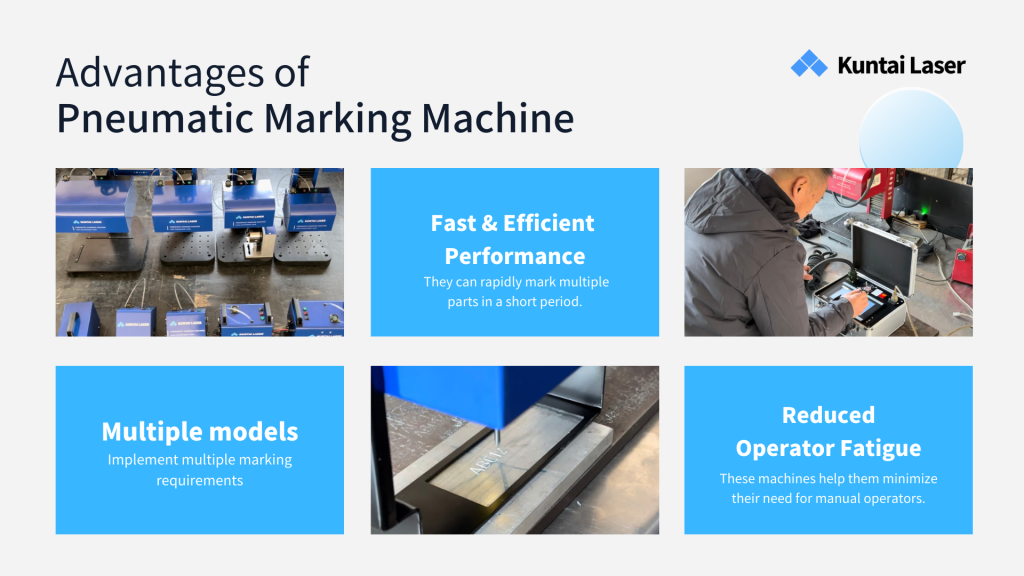

空気圧マーキングマシン:完全ガイド

Table of Contents Pneumatic marking machines are known as game-changing devices in industrial engraving as they offer an enduring, efficient, and versatile approach to marking diverse materials. They are powered by compressed air and craft permanent indentations suitable for text, logos, serial numbers, barcodes, and many more. These machines are today widely used in multiple industries such as automotive, aerospace, and manufacturing because they deliver dependable traceability and compliance. Unlike laser or inkjet marking, pneumatic technology is recognized for its cost-effectiveness and powerful functionality, even in demanding environments. Our comprehensive guide today aims to discuss all the advantages, disadvantages, applications, and fundamental considerations you need to know before choosing a […]

CO2 レーザーマーキングマシン: 究極のガイド

Table of Contents CO2 laser marking machines have reshaped how businesses build permanent and high-quality markings on different materials. They can precisely and quickly create markings for barcodes, logos, or intricate designs that are never possible with traditional methods. These machines are broadly employed in different industries such as packaging, electronics, and automotive. In these industries, clear and long-lasting markings are vital for traceability, branding, and compliance. The CO2 laser marking technology can handle a wide set of materials such as wood, leather, glass, and plastics. In our post today, we aim to deeply review CO2 laser marking machines, their advantages and disadvantages, applications, pricing, and more. What is a […]

クンタイレーザーが無錫太湖女子ハーフマラソンをサポートし、栄光の瞬間を刻む

Kuntai Laser, a high-tech enterprise with 25 years of technological expertise, is committed to empowering global manufacturing. Our products, including laser marking machines, laser welding machines, and laser rust removal machines, are widely praised in the industrial sector for their precision, efficiency, and durability. As a sponsor of the event, Kuntai Laser will once again use its professional laser engraving technology to customize exclusive medals for every runner who finishes, ensuring their moment of glory is eternally commemorated. Our laser engraving technology leaves permanent markings on metal surfaces, resistant to wear and tear. From the initial sample to the final engraved result, our team conducts multiple tests to ensure each […]

パキスタンの顧客 | 2025年2月、現地でマーキングと溶接機のテストを実施

Kuntai Laser were pleased to host two esteemed clients from Pakistan at our KunTai Laser factory! They had the opportunity to visit our facility, test our machines on their own samples, and engage directly with our dedicated sales team, who provided detailed demonstrations of our products and their capabilities. As a leading source manufacturer with over 20 years of experience, we are proud to export our laser marking, cutting, and welding machines to multiple countries worldwide. We are now actively looking for reliable agents and distributors globally. We also extend a warm invitation to customers from all regions to visit our factory in person. You can learn more about our […]

2024年世界人工知能会議(WAIC)におけるKuntai

Kuntai Laser attended the 2024 World Artificial Intelligence Conference (WAIC) held at the Shanghai Expo Center. Our team gained a deep understanding of the latest AI technologies and their applications in various industries such as healthcare, finance, and manufacturing. This conference was not only a platform for learning and exchange but also highlighted how Kuntai Laser can integrate laser technology with AI to explore the potential synergies between the two, creating more possibilities for industrial applications. At the exhibition, we encountered many companies developing AI humanoid robots. On their production lines for humanoid robots, Kuntai Laser’s laser engraving, marking, and cutting equipment can enhance the following processes: This year’s exhibition […]

第4回イノベーションフェア無錫-ヨーロッパ国際技術交流会議 – ゲストとしてKuntai Laser

Kuntai Laser, a leading company in China’s laser equipment manufacturing industry, recently represented China at the 4th Innovation Fair Innovation Cross-border Exchange Conference and Wuxi European Enterprise Matchmaking Conference held at Wuxi Taihu Huayu Hotel. This important cross-border exchange event brought together more than 70 government and business representatives from 40 companies in European countries such as Germany, Italy, and Spain, promoting international cooperation and highlighting the strength of China’s manufacturing industry on the global stage. Kuntai Laser seized the opportunity to introduce specialized laser machines to potential partners. For example, it recommended its large-format laser cutting machine to a Spanish fabric manufacturer, which is suitable for fast and accurate […]