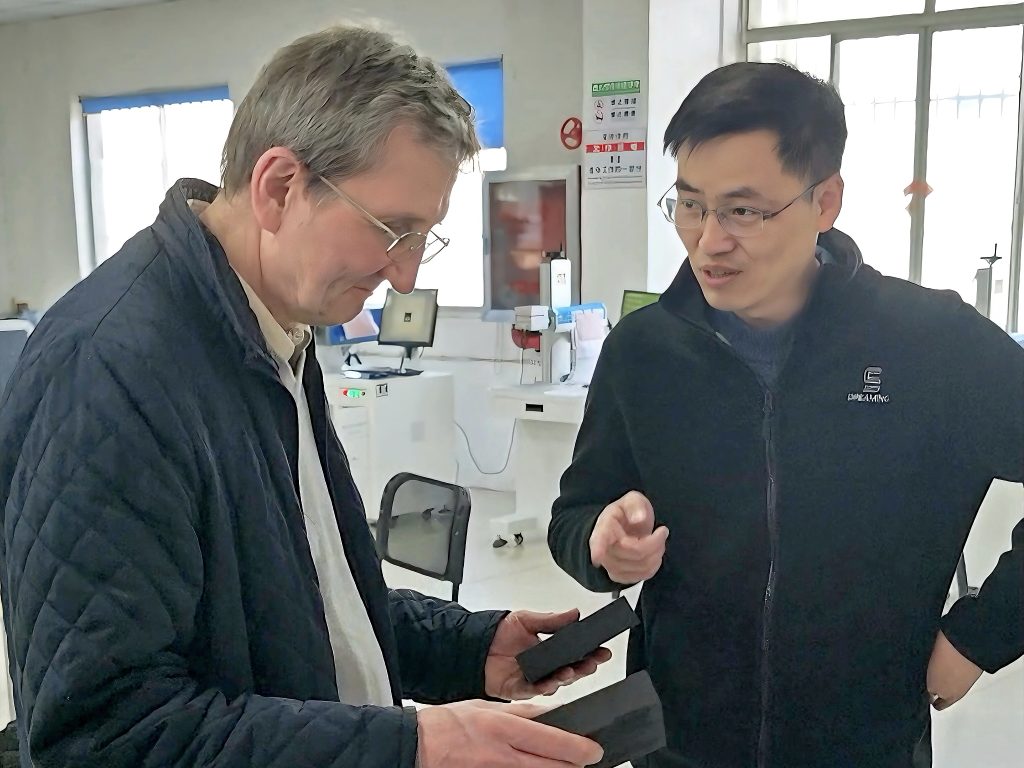

U.S. customer | June 2025, Large Format Laser Marking Machine Sample

This week, Kuntai Laser had the pleasure of welcoming two esteemed clients from the United States for an in-depth factory visit and technical exchange. The visit was coordinated directly by our senior engineering team, ensuring a professional and solution-focused experience. The clients brought their own workpiece samples, which were tested on our large-format fiber laser marking system. During the demonstration, our engineers provided a comprehensive overview of the machine’s performance capabilities, including marking accuracy, adjustable power settings, and its adaptability across a range of materials and applications. The successful test results fully met the clients’ expectations for marking quality and consistency. In addition to fiber laser marking, the clients also […]

Pakistani customers | June 2025, Gain deep insight into our laser equipment strength and performance.

Recently, our company welcomed an important customer from Pakistan, who made a special trip to visit our factory for a field visit and inspection. The purpose of this visit is to gain an in-depth understanding of our company’s comprehensive strength and product performance in the field of laser equipment, and to have in-depth exchanges on future cooperation matters. Accompanied by the relevant person in charge of the company, the customer visited our production workshop, assembly line and finished product display area, and fully understood our company’s research and development and manufacturing processes for laser marking, laser cleaning, laser cutting, laser welding and other equipment. During the period, our employees introduced […]

Bangladeshi Customer | May 2025, Explore Laser Marking of non-metallic materials

This week, KUNTAI LASER has honored to host a customer from Bangladesh. The focus of this visit was the evaluation of UV laser marking machines, with in-depth testing of performance under different power levels. The results were highly satisfactory and laid a solid foundation for potential future collaboration between the two parties. I. Visit Overview: Efficient Tour and Hands-On Testing II. Discussion Outcomes and Future Collaboration Outlook Following the testing session, the client engaged in in-depth discussions with our sales and technical teams regarding equipment selection, customization requirements, and after-sales support structures. The client emphasized that the hands-on testing significantly increased their confidence in Kuntai Laser’s product reliability, process controllability, […]

Sir Lanka Customer | May 2025, Laser marking and welding on automobile components

This week, KUNTAI LASER had the honor of welcoming a distinguished customer from Sri Lanka — a manufacturer specializing in automotive components — to our headquarters and production facility. The visit was part of the client’s evaluation process to identify reliable and advanced laser equipment suppliers capable of supporting their growing production demands. Overview of the Visit The customer’s delegation included the company’s procurement manager and technical engineers. The primary objectives of the visit were: We began the visit with a guided tour of our production workshop, assembly line, quality control area, and testing labs. Our team provided detailed introductions to our manufacturing standards, internal inspection procedures, and equipment calibration […]

A brief discussion on the application of laser technology in industry

Table of Contents A brief discussion on the application of laser technology in industry A laser is one of the very important instruments of modern industry, which creates unique advantages of precision, speed, and efficiency across a broad spectrum of fields. From cutting, welding, and engraving to the cleaning of parts, laser systems are replacing modern product manufacturing activities across industries. The levels of manufacturing standards, coupled with increasing emphasis on automation, will continue to swell the applications of laser systems. This flexibility allows laser system applications in processing different materials within several sectors, such as automotive, aerospace and defense, electronics, and medical devices. Laser systems are better alternatives in […]

How does the jewelry laser welding machine weld and repair jewelry?

Table of Contents How does the jewelry laser welding machine weld and repair jewelry? Jewelry laser welding machines have become the hallmark of jewelry making, ushering precision and efficiency into the blueprints of both manufacturing and repair of fine jewelry. These machines utilize very intense light beams, outstandingly joining metal pieces with high precision targeted for delicate and intricate design work. For example, resizing a ring, reattaching a gemstone setting, or repairing a broken chain would be performed without taking away from the integrity or the appearance of the jewelry. By low heat distortion, compatible with welding various metals, laser welding has established itself as an important modern machinery in […]

How to Choose the Right Laser Cleaning Machine for Your Factory?

Table of Contents How to Choose the Right Laser Cleaning Machine for Your Factory? In this rapidly industrializing world, keeping surfaces clean, free of rust, and being appropriately prepared is crucial to efficiency, product quality, and safety. Conventional cleaning systems either ruin the material, take time, or pollute the environment. This is where laser-cleaning technology provides an efficient, precise, and environmentally safe alternative. With so many varieties of laser-cleaning machines differing in power and features, how does one choose one for the factory? This is not just a question of selecting the most powerful machine; it is one of matching the proper specifications, features, and design with your unique requirements […]

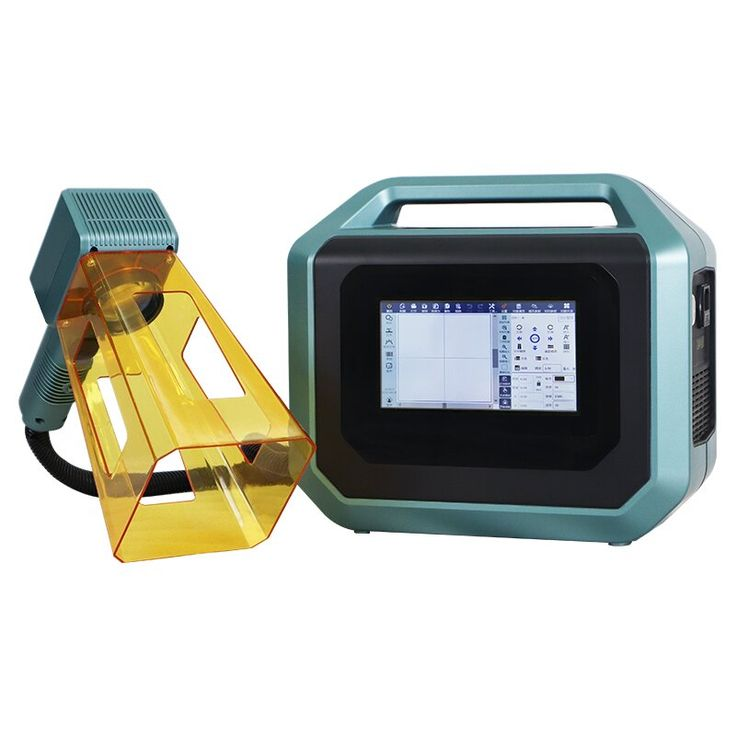

Why are portable laser marking machines becoming more and more popular?

Table of Contents Why are portable laser marking machines becoming more and more popular? Efficiency, mobility, and precision are key things in most industrial and creative apparatuses today, and this is where portable laser marking machines establish themselves as a mainstay. They are indeed revolutionizing the engraving, branding, traceability, and even customization processes for several materials, compact and easy to carry. Be it manufacturing, automotive, electronics, or even arts, the market seems to be on a roll about ever-increasing flexible marking solutions. Due to this, portable laser machines have become highly popular. Why could most professionals and small businesses prefer portable laser marking machines over traditional setups? This article tackles […]

TIG Welding vs. Laser Welding: The “Light-Speed Evolution” of Manufacturing

In modern manufacturing, welding technology is an indispensable process for joining metal components. With technological advancements, welding methods have continuously evolved—from traditional Tungsten Inert Gas (TIG) welding to today’s advanced laser welding. Each technique has its unique strengths. Today, we’ll take an in-depth look at the differences between these two welding methods, highlight the technical advantages of laser welding over TIG welding, and introduce the exceptional capabilities of Kuntai Laser Welding Machines. Technical Principles & Core Differences TIG Welding vs. Laser Welding Energy Transfer Mechanism Material Compatibility Kuntai Laser’s Laser Welding Application on metal stand Why Laser Welding is Better Than Traditional Welding

China Customer | April 2025, Onsite Operate Laser Cleaning Machine for clamp cleaning

Kuntai Laser recently completed an onsite installation of our laser cleaning machine for a valued customer in Suzhou, Jiangsu, CN. Our team provided hands-on training, demonstrating efficient and safe operation of the equipment for cleaning metal clamps. We’re proud to support our clients with both advanced technology and reliable service to ensure smooth implementation and optimal results. Showcasing Laser Cleaning Results:Before & After