レーザー溶接で宝石をセット

Accuracy and efficiency offered by laser welding help to change the jewelry and fashion industry. Setting gemstones typically makes use of it since it provides safe connection free from damage to the stones or surrounding metal. Perfect in fashion for creating intricate designs on delicate textiles, laser welding guarantees lifetime and design consistency. Minimal heat-affected zones help to prevent material distortion and discoloration by means of which Furthermore allowing non-contact procedures, laser welding helps to lower the danger of harm to delicate materials. Its great accuracy lets complicated designs and fixes possible, so boosting innovation and quality of products. Furthermore, environmentally sustainable and reasonably affordable since it lessens the demand […]

ジュエリーの表面から酸化物とゴミを取り除く

ジュエリーのレーザー洗浄は、金属表面から酸化物やゴミを取り除き、損傷を与えることなく本来の輝きを取り戻すために使用されます。この方法では、宝石も洗浄でき、不純物を取り除き、透明度を高めるのに役立ちます。レーザー洗浄はファッション業界で、繊細な生地から汚れやシミを取り除き、質感と外観を維持するために使用されています。レーザー洗浄は、非接触技術であるため、素材に損傷を与えるリスクが軽減されるという利点があります。環境に優しく、有害な化学物質やゴミは発生しません。さらに、費用対効果が高く効率的なレーザー洗浄は、過酷で時間のかかる従来の洗浄技術の必要性を最小限に抑えるのに役立ちます。

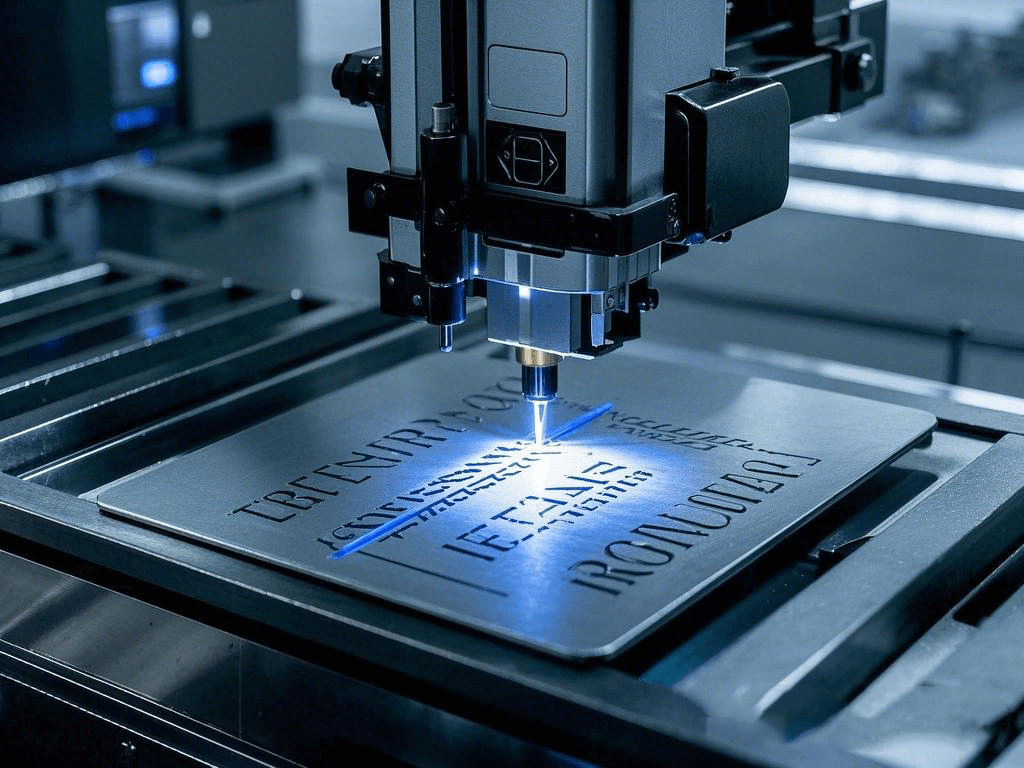

ジュエリーにレーザーマークのデザインパターンと文字を刻印

Laser marking is a transforming tool with accuracy and customizing in the jewelry and fashion sectors. Mostly found in jewelry, engraving customized inscriptions and complex designs on items like rings, necklaces, and watches is done on By precisely stamping highly exact brands, initials, and even images, this method enhances the visual appeal and originality of every object. Fashion uses laser marking to create unique designs on accessories and fabrics, therefore adding some exclusiveness and flair. In terms of non-contact technology, laser marking avoids damage to delicate materials and has capacity to produce permanent, high-contrast marks resistant to wear and fade. Since it uses no harmful chemicals or creates no waste, […]

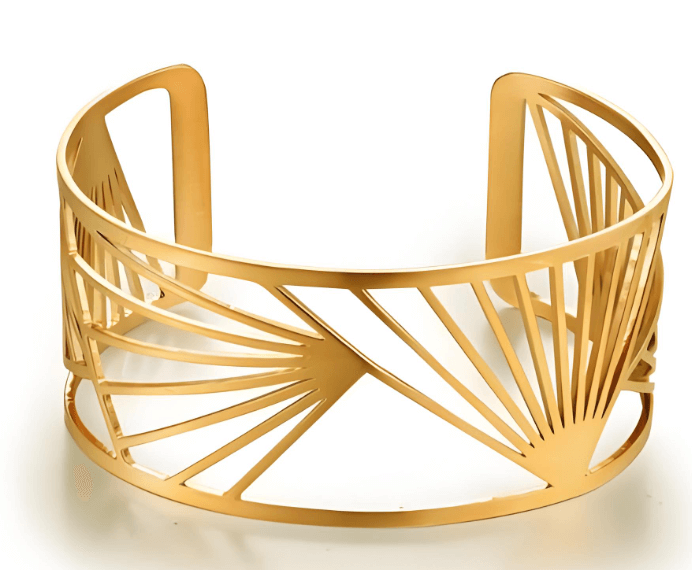

金属、ガラス、クリスタルのカットモチーフ

Laser Cutting is a developing technique with accuracy and creativity promised. In jewelry, it is used to make complex motifs in metals such gold, silver, and platinum, therefore allowing beautiful patterns and unusual objects before difficult to obtain. Moreover improving the range of materials utilized in jewelry design is the cutting capacity of non-metal materials like glass and crystal. Perfect in fashion for making intricate motifs on materials like leather and lace, laser cutting offers an amazing degree of accuracy and detail. Since laser cutting maximizes material consumption and lowers the need for further finishing operations, it leaves less material waste. Moreover non-contact, it guarantees a flawless edge finish and […]

溶接による堅牢ですっきりとした家具の接続

Because of its accuracy, efficiency, and capacity to handle many materials with low thermal distortion, laser welding has grown to be a useful technique in the furniture and wooden products sectors. Laser welding is frequently used in the furniture industry to create strong, flawless connections between metal components including steel frames, hinges, and brackets with hardwood elements without the requirement of bolts or screws. 1. Welding for Furniture Connection and Fixing Particularly for metal and composite furniture, laser welding is widely employed in the furniture sector to create robust, long-lasting bonds between several portions of the structure, including frames, legs, supports, and furniture component parts. Highly exact welds made possible […]

家具のブランド、パターン装飾、製品IDをマークする

Both practical and decorative uses for laser marking are somewhat extensive. Whether furniture components are made of wood, metal, or another material, the accuracy and versatility of laser technology let producers create complex designs, logos, and patterns on them. Engraving logos, product information, and serial numbers for identification in branding and labelling. Creating distinctive patterns and textures on furniture for modern and high-end designs will help to accentuate their features.Custom Furniture: Providing bespoke or luxury item customising engravings.Part marking with batch numbers for traceability helps to control quality. Positive aspects:1. Accuracy and Detail: Provides great ability for complex designs.2. No Physical Contact: Helps to avoid damaging fragile objects like glass […]

家具製品用のカットパネル、脚、金属ブレースなど

For its accuracy, adaptability, and capacity to create complex designs on a range of materials, laser cutting is increasingly used in the furniture and wooden products sector. It helps producers to reach high degrees of detail that would be challenging or unattainable with conventional cutting techniques, such complex carvings, curves, and exact geometric forms. Process: 1. Cut raw materials into the required sizes by laser cutting, such as panels, legs, shelves, or supports. 2. Assembled these elements. Sometimes extra strength is given by metal braces or reinforcements. 3. To guarantee the pieces have a smooth surface and desired aesthetic look, the last stage consists in finishing touches like sanding, painting, […]

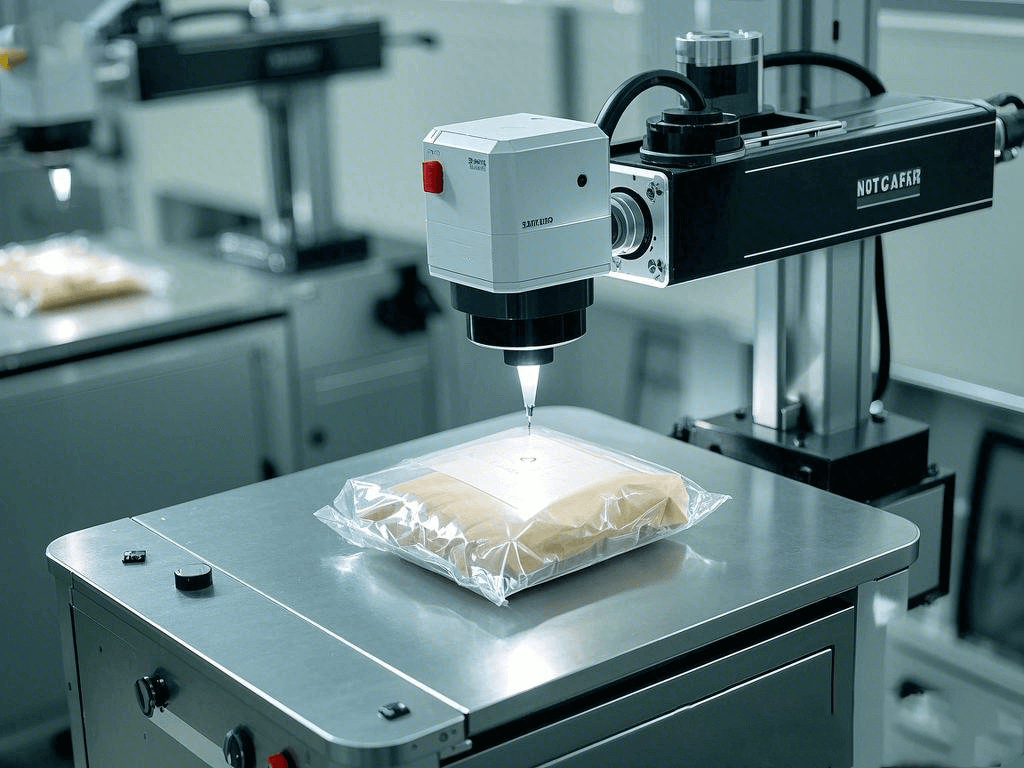

レーザーカットパッケージ、ラベル、ステッカー

Cutting for a more individualized form and appearance. Creating useful, aesthetically pleasing, and safe food packaging depends on cutting, which also lets one better customize, use easier, and comply with hygienic regulations. To accommodate various products, packaging materials including cardboard, pouches, and plastic films must be cut to particular sizes. Perfect measurements made possible by laser cutting guarantee that the packaging fits exactly around the product, therefore minimizing waste and enhancing shelf display. Many food containers call for cuts or perforations to let consumers readily access the contents. Clean, exact perforations or notches produced by laser cutting will guarantee that packaging opens without ripping or jeopardizing the contents. Cardboard and […]

プラスチック、ガラス、金属への有効期限、バッチコード、ロゴのマーキング

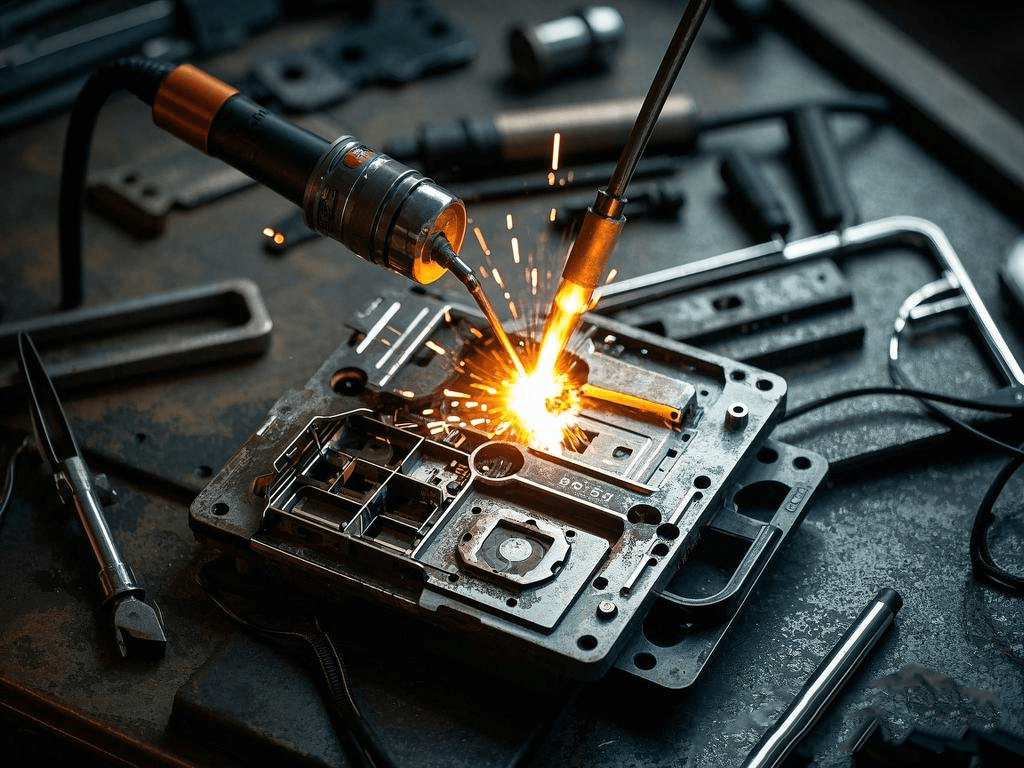

電子機器の繊細な部品や外装の溶接

The electronics sector uses laser welding extensively to connect parts like circuit boards, batteries, and casings in devices such laptops and smartphones. Small, fragile parts would find it perfect for its accuracy, speed, and ability to produce strong, clean welds free from extra materials. Common application: 1. Smartphone and LaptopWithout compromising delicate parts, it provides accuracy, low heat impact, and robust welds. 2. Outer casing and battery housesElectronics’ outer casings and battery housings are joined using laser welding, which produces exact, robust welds free of damage to interior components. Benefits include: PrecisionMinimal Heat ImpactStrong, Durable jointFast and Automated Clean and Neat