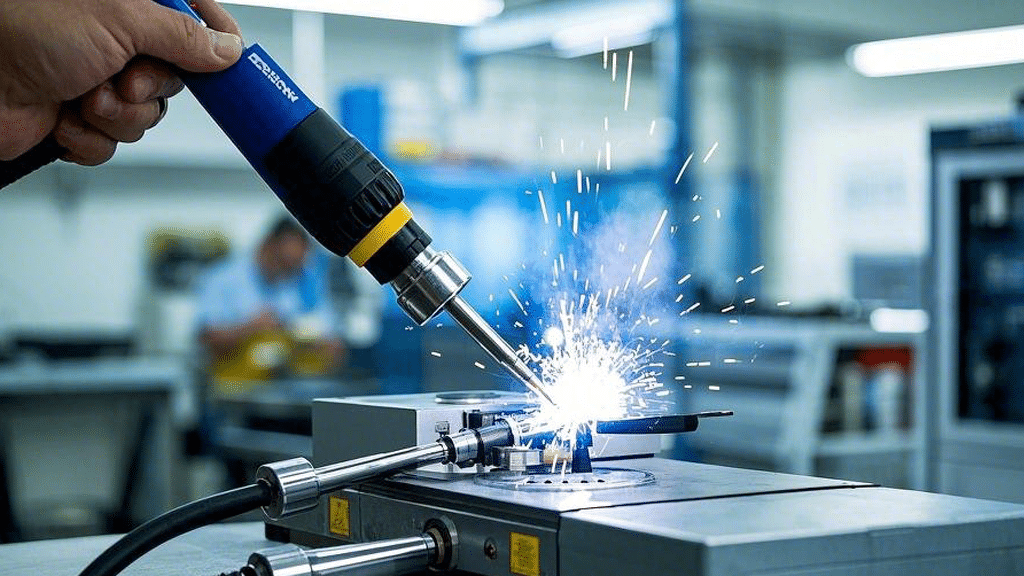

低HAZと高精度の溶接金属ツール

Precision and adaptability of laser welding contribute to explain its growing popularity in the tool and industrial sectors. It is widely used to combine tools and equipment parts to guarantee proper and strong bonding free from material distortion. Its ideal for changing and fixing dies and molds to increase lifetime and save downtime is this technology. Reduced heat-affected zones and great accuracy of laser welding help to prevent damage to fragile parts. Its non-contact approach fits premium manufacturing since it lowers wear and contamination risk. Additionally very compatible with automation is laser welding, therefore improving manufacturing process consistency and efficiency.

ツールに安全警告、シリアル番号、ロゴをレーザーでマーク

Laser marking is also used to provide complete safety warnings and machine instruction, so improving user safety and operational effectiveness. Its accuracy and lifetime find great application in machinery and tools; serial numbers, logos, and other identifying markers abound on tools and industrial components. This guarantees all through manufacturing traceability and quality control. Non-contact properties of laser marking help one to avoid harm to fragile surfaces. Its great accuracy also allows complex and continuous marks resistant to fade-through to be seen. Moreover, environmentally beneficial is laser marking as it does not produce any dangerous waste or demand for chemical inks.

レーザーカット金型と部品の形状

Laser cutting is extensively applied in the tools and machinery sector: commonly used for dies, molds, cutting and shaping tool components allow complex designs and great accuracy. This method is quite helpful for designing intricate metal parts needed for different items by means of complexity. One of the main advantages of laser cutting is its non-contact technique since it lowers material deformation and wear. Its tremendous speed and efficiency also aid to reduce manufacturing costs and delays by means of Since laser cutting can control a wide spectrum of materials, it is also versatile for numerous purposes. Maintaining consistency and quality of products depends on every component being constructed to […]

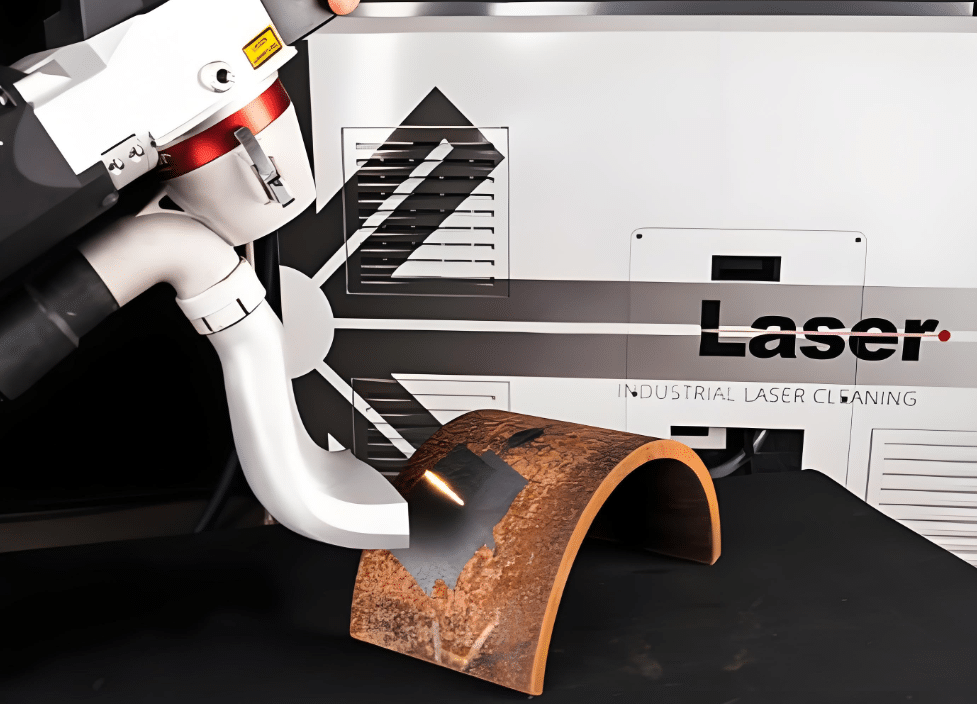

ツール表面から錆、油、汚染物質を除去する

Laser cleaning is extensively used to clean metal surfaces from rust, oil, and other contaminants so that tools and machinery components are clean and ready for extra manufacture or operation. Since it eliminates contaminants that can damage the bond, this method is extremely efficient for surface preparation before to welding or painting. Moreover, mold maintenance uses laser cleaning to eliminate leftovers without compromising the surface integrity of the mold. Laser cleaning has benefits in terms of non-contact technique, which reduces material damage risk. Since it generates no waste or use dangerous chemicals, it is ecologically benign. Moreover, laser cleaning is quite flexible, able to manage different materials and contamination levels, […]

太陽光パネルと風力タービンのレーザー溶接

Laser welding precisely and fast meets the particular requirements of these technologies from improving the structural integrity of wind turbine gears to guaranteeing the lifetime of solar panel connections. 1.Solar Panel Solar panels’ metal components—including frames, junction boxes, and connectors—are joined using laser welding. It guarantees robust, exact welding without compromising the delicate cells, therefore improving the panel’s electrical conductivity and endurance. Laser welding aluminum frames and electrical connections seals them, therefore shielding the panel from outside influences.Precision welding produces dependable low-resistance electrical connections. 2. Wind Turbines Especially for rotor blades, towers, and gearboxes, wind turbine construction depends on laser welding. It lowers component weight and stress while yet producing […]

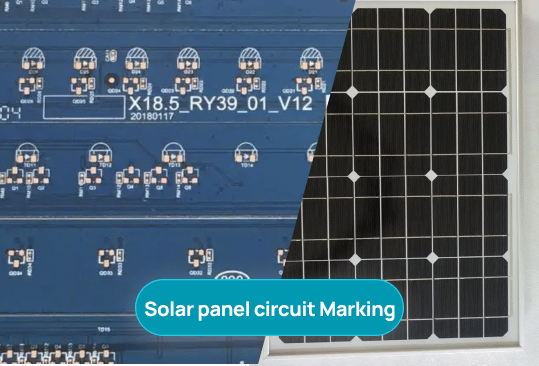

再生可能エネルギー産業におけるレーザーマーキング

Across solar panels, wind turbines, and energy storage systems, laser marking in the renewable energy industry improves traceability, inventory control, and maintenance efficiency. It is a necessary instrument for the sector since it improves product quality and lifecycle management by offering permanent and exact marks. Solar Panels: Easy identification in case of recalls or replacements. – serial numbers– QR codes– manufacturer details Wind Turbines: Facilitating maintenance tracking by marking repair or servicing history.– serial numbers and installation dates. Batteries: Ensuring quality control with unique identifiers, and help with inventory control– serial numbers for inventory control.

レーザーマーキング

1. Marked Holographic Stickers permanently – Marking with laser-precision helps to preserve your brand by discouraging copycats.– Laser marking creates bright, non-fading text on reflective surfaces, therefore simplifying reading of expiration dates, batch numbers, and other vital information.– Laser-marked or sliced seals boost security. Consumers treat items carefully should stickers be taken off or damaged. For safety warnings or advertising, laser-marked holographic labels offer exceptional functionality and a great visual appeal. 2. Detailed artwork and coded beverage can – Laser marking instantly put batch numbers, QR codes, or promotional messaging on cans.– Handle limited-edition designs or regular product runs using small, delicate text for lot numbers or expiration dates on […]

レーザーカットを使用した精巧な梱包(段ボール、箱、袋)

Plastic bags and basic cardboard boxes are no more. Modern laser cutting is stretching labelling and packaging restrictions. 1. Stylish and airily perforated cardboard boxes – Ventilation: By moving air in packaging for baked products and fresh food, enhances freshness. – Laser-cut design sets your product apart from a standard brown box. For corporate logos or geometric designs, laser technology can precisely cut accurate cardboard forms, creating an arresting visual impact that appeals to premium, environmentally sensitive consumers. 2. Windowed Box featuring elaborate circular cutout You can create exactly specified laser-cut windows. Editing a digital file calls for no new dies or setup to alter themes or proportions. – Product […]

医療業界向け精密レーザーマーキング

Given their crucial importance in patient care and safety, medical device criteria for accuracy, durability, and traceability are strict. Medical equipment has to satisfy strict criteria for regulatory compliance, sterilizing capability, and functionality. Offering a precise, permanent, non-contact solution for marking medical instruments, implants, and equipment, laser marking technology has shown to be a great aid in satisfying these needs. Scalpels and forceps upon sterility requirements, non-contact marking and clear marking also ensure no wear and traceability of the markers upon reuse. Implants: It offers non-invasive, permanent identification capable of surviving the lifetime of the implant. Syringes and Needles: Usually marks such lot number, date, etc., syringes and needles.Neither compromise […]

正確で繊細な医療機器の溶接

Laser welding is perfect for the complicated and delicate components sometimes found in medical devices since it offers outstanding accuracy. By focusing the laser on small, detailed areas, producers can produce excellent welds on components with fine characteristics, such surgical tools, medical implants, and diagnostic equipment, or in close proximity to each other. One non-contact technique that lowers the danger of contamination is laser welding. In the medical field, this is especially important since the addition of foreign particles or contaminants into the welding joint can threaten the sterility or safety of the device. Controlled settings allow laser welding to be carried out, therefore reducing the possible contamination risk. Diagnostic […]