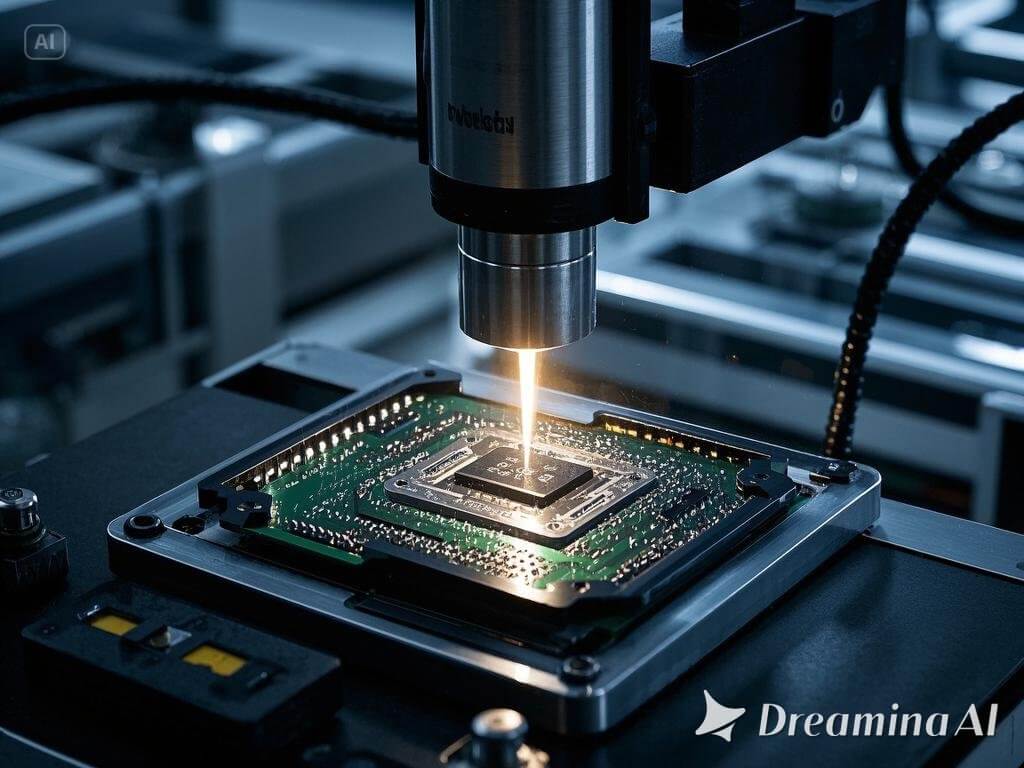

エンブレム、バッチ番号、QRコードでマークされた電子部品

Different parts in the electronics sector need laser marking for a different use. Particularly with small and complex items, laser marking is used for its accuracy, speed, and durability. Laser marking technology finds extensive application in three primary forms of components in the electronics sector: 1. Electronic components—such as manufacturer emblems, batch numbers, date codes, and product numbers—need highly exact identification. 2. Casings and accessories—need to be marked with barcodes, QR codes, safety certifications, product information, and brand logos. 3. Connectors and cables—Laser marking can mark these information including identification, specifications, batch numbers, etc. to enable installation, repair and product traceability, therefore guaranteeing correct connection and quick identification during later […]

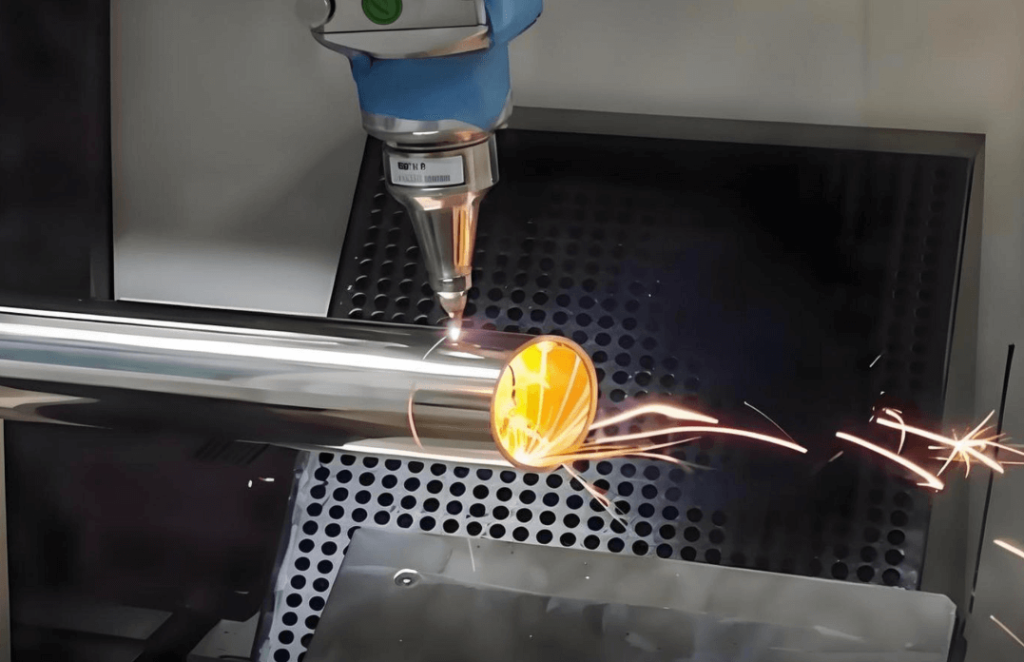

金属で作られた溶接用品

The key reasons laser welding is chosen are its ability to generate high-quality, strong welds with low heat input, which reduces the danger of distortion or damage to delicate materials. Advantages: 1. Minimal Heat Distortion Laser welding adapt to aluminum or thin stainless steel, which are sensitive to heat, preventing distortion and guaranteeing the welded seams keep their original shape and strength. 2. Precision and Clean Welds Laser welding excels in joining thin metal parts that are ubiquitous in home appliances.It ensures the product is beautiful, wear-resistant and long-term useful 3. Enhanced product safty Consumer Goods have a wide range of application scenarios. Laser-welded items can be utilized in a […]

日常のアイテムにロゴ、シリアル番号、バーコードをマークする

Laser marking is suitable for a wide range of everyday items Laser marking is based on the interaction between the energy of the laser and the surface of the substance that causes either physical or chemical changes to the material.Changing the laser type and the process settings will help one to fit different materials. Advantages cannot be missed Versatility Across Materials:including metals, plastic, glass, woods, etc. Cost-Effectiveness:Once set up, it works continuously Precision and Permanence:Unlike conventional marking techniques that could fade over time, laser marking offers very exact, precise, and clear engravings. Eco-friendly: Not one chemical or abrasive used. Why you choose laser marking? Because of its accuracy, speed, and […]

レーザーカットアクリル、段ボール、フォームボード

Why choose laser cutting? 1. Without specific tools, laser cutting can be applied on a great range of materials, therefore simplifying the manufacturing process and lowering expenses. 2. The main reasons laser cutting is selected are its capacity to deliver great precision with clean, smooth edges, therefore lowering the requirement for additional finishing. Focusing a high-powered laser beam onto materials like acrylic, cardboard, or foam board, laser cutting melts, burns, or vaporizes the material along the cut line. Acrylic: The laser melts the acrylic and directs the material away to produce exact, flawless cuts. Cardboard: The laser vaporizes the cardboard so that it leaves sharp, clean edges free of burning. […]

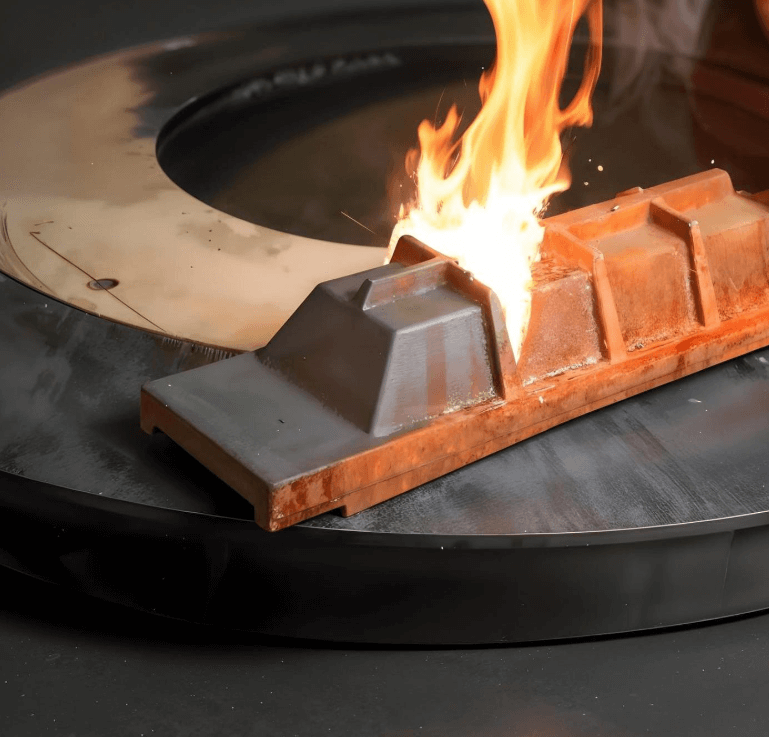

表面の汚れや油絵の具をきれいにする

Laser cleaning removes dirt, corrosion, oil, and paint by guiding highly intense laser beams at a surface. While leaving the underlying material undamaged, the undesired material absorbs the laser energy and heats up, vaporizes, or is ablated. Why cleaning is neccessary? Effective removal of elements including rust, filth, oxidation, and paint—which can build over time and compromise the appearance and performance of the product—requires laser cleaning. Adjusting the power, frequency and speed of the laser is critical to ensuring a clean surface on different materials without causing damage,such as: Rusty metal utensils:Remove the copper smell Painted items:Cleaning the paint surface

鉄骨構造物の切断

Laser cutting has several advantages in the building industry. It guarantees that, for structural integrity, components including beams and trusses are cut to exact standards. It provides very great accuracy and clarity. The remarkable efficiency of the technique reduces processing time and material waste, therefore providing a reasonably priced replacement. The fact that laser cutting can be used on a wider range of materials—including metals and non-metals like glass—expansions of its application in architectural designs. Applications for steel constructions guarantees suitable and robust beam, column, and trusses cutting capacity. By cutting robust constructions in metal sheets and pipes, this technique allows complicated forms matching architectural criteria. Moreover, tremendous precision and […]

レーザー洗浄による表面コーティングの準備と酸化の除去

Laser cleaning is becoming more and more common in the building sector since it can safely remove stains like paint, rust, and other pollutants from surfaces. Eliminating oxidation and corrosion helps mainly to restore metal surfaces like steel beams and aluminum facade. Laser cleaning is often used to prepare surfaces for coatings or adhesives therefore guaranteeing appropriate adhesion and extending the life of the applied materials. Graffiti cleanup also depends on it since it provides a cheap and ecologically friendly substitute.

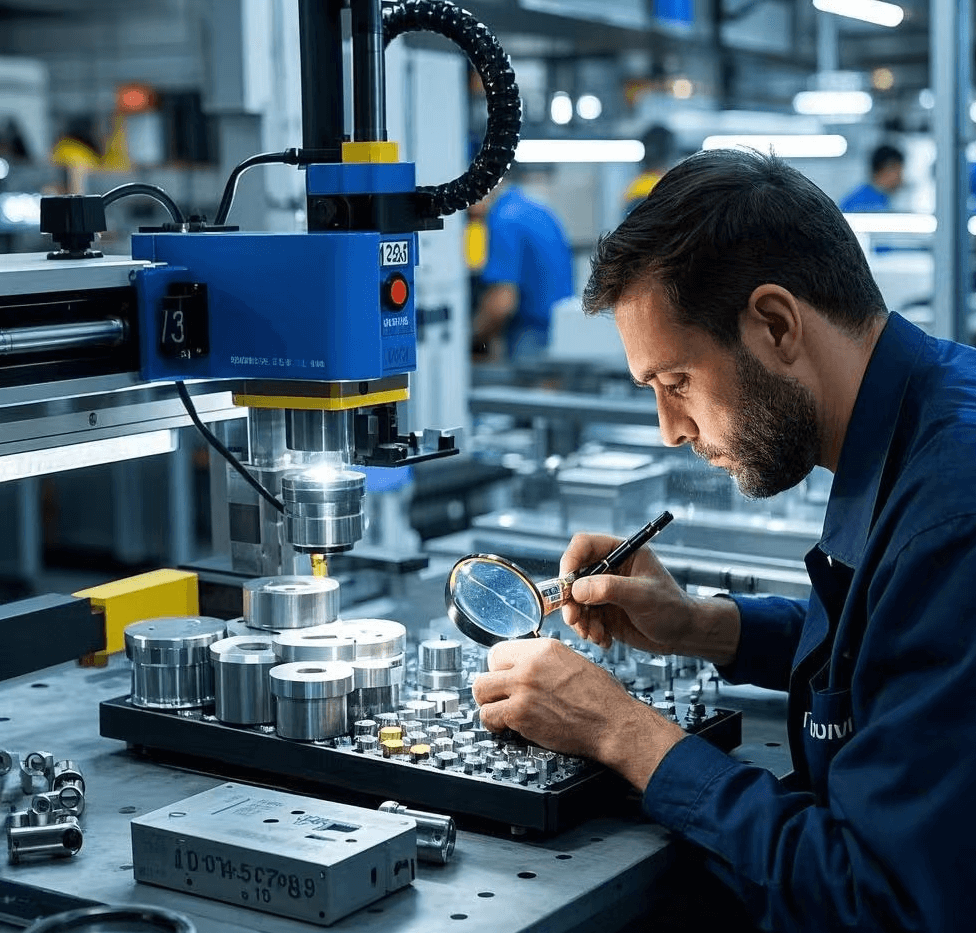

正確な組み立てと追跡のために建築資材にマークを付ける

Laser marking is growing in popularity in the building industry especially for its accuracy, robustness, and flexibility. Its major application is in structural component labeling. By marking steel beams, columns, and other unique identifiers, construction workers can ensure accurate assembly and tracking. This reduces mistakes and accelerates the building process especially in complex projects where components are built off-site. Laser marking also produces permanent marks on building materials, such as safety warnings and instructions, which remain clear all during the lifetime of the construction. Its capacity to identify several materials without damage raises its value in building. As technology evolves, laser marking remains rather crucial for the building industry in […]

レーザー溶接による構造の完全性の向上

Laser welding offers precise, rapid, adaptable solutions changing the construction. In structural steel building, it enables quick assembly of complex components with minimum distortion, hence enhancing the integrity and endurance of bridges and tall structures. Its flawless accuracy for prefabricated components like roof systems and wall panels reduces on-site welding time and increases quality. Furthermore, it allowing intricate metal facade designs are decorative applications of laser welding. As technology advances, laser welding continues to be increasingly important in inspiring efficiency.

レーザー洗浄による美術作品の修復

In the world of painting and decoration, laser cleaning is a developing technique providing accuracy and flexibility. Restoring historical items and artworks requires the removal of old varnish, dirt, and grime without harming the underlying surfaces. This is quite effective when cleaning delicate artifacts like ancient paintings, bronze statues, and marble sculptures—where conventional techniques could be harsh and destructive. Laser cleaning removes graffiti on architectural surfaces as well, therefore preserving the original design integrity. The non-contact and non-invasive nature of laser cleaning lowers the risk of damage to expensive goods by way of which benefit It is also ecologically friendly as it creates no waste or use harmful chemicals. Its […]