米国の顧客 | 2025年2月、金属銘板レーザーマーキングのコスト効率の高いソリューションの検討

金属銘板レーザーマーキングのコスト効率の高いソリューションの探求

エンジニアのJ.Huが統合マーキングシステムの設計について語る

Personalized Automated Laser Marking System Join J.Hu, our expert Mechanical Design Engineer, as he explains the development of an automated laser marking system designed specifically for a top new energy company. Get an inside look at the precision and professionalism that Kuntai Laser brings to each project. See how we meet complex industrial needs with innovation and expertise. Design Philosophy He offers a comprehensive walkthrough of his latest project—an automated laser marking system tailored for a leading new energy company. In this video, J.Hu introduced his design philosophy and explore the meticulous planning behind this innovative solution. Find out Kuntai Laser expertly meets complex industrial demands with precision and professionalism. […]

パルスレーザー洗浄機:決定版ガイド

Table of Contents Pulse laser cleaning machines have successfully revamped the surface cleaning technology as they come with the utmost precision, efficiency, and eco-friendliness. These machines take advantage of laser beams to help you get rid of contaminants such as rust, grease, and paint. They provide remarkable cleaning results without harming the underlying material. Traditional cleaning techniques come with abrasive chemicals or physical scrubbing, and this is where pulse laser cleaning machines shine because they are non-contact and sustainable. This is a huge benefit for industries that demand meticulous cleanliness and surface integrity. Regardless of the industry your business lies in, pulse laser cleaning machines can handle the diverse cleaning […]

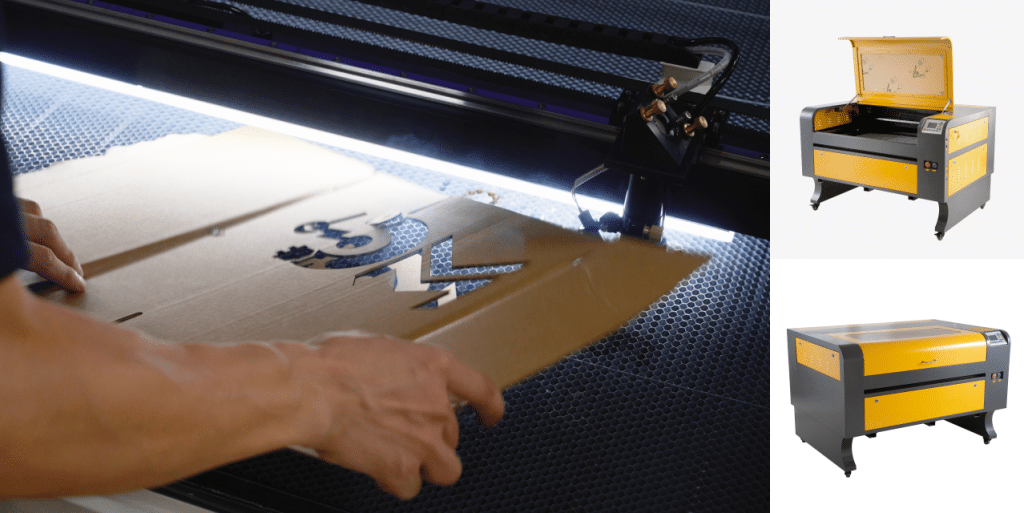

アクリルへのレーザー彫刻

All-in -one Laser Welding Machine Choosing the right equipment can make or break your production line. For Acrylic material, CO2 Laser Engraving machine is the best choice. High-Speed CO2 Lasers – They can engrave large areas of acrylic at breathtaking speeds( 1500mm/second) – For high-volume production, consider a CO2 laser with a large work area and automatic material feeding system. – While not as precise as fiber lasers, CO2 machines can still achieve impressive accuracy, typically around 0.1mm. For most acrylic applications, this is more than sufficient. Product Recommendation KT-LF Series

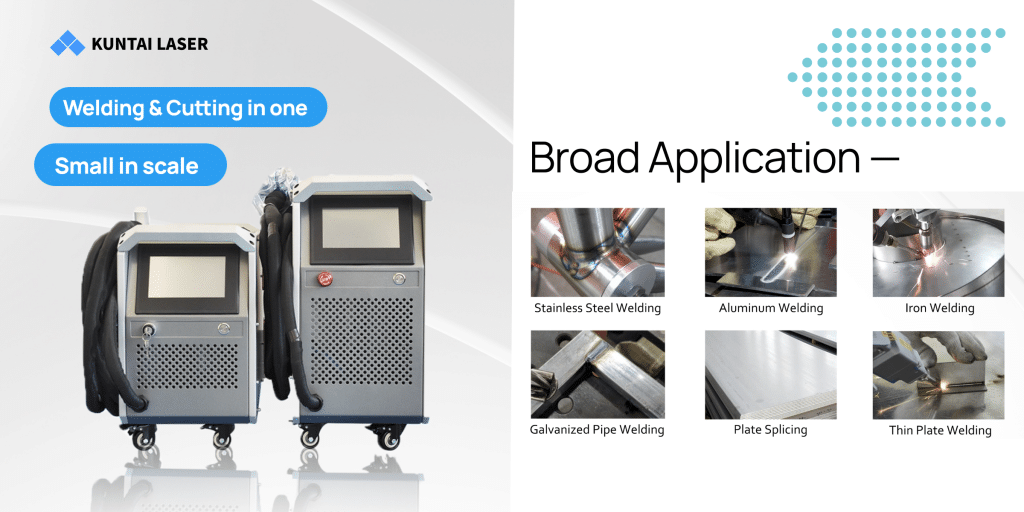

オールインワンハンドヘルドレーザー溶接機のご紹介

All-in -one Laser Welding Machine Operate Cut, Weld, and Clean using one machine In metalworking, cutting, welding, and cleaning are closely related. With our new handheld laser welding machine, Kuntai Laser gives engineers a complete laser welding system to handle the above three operations together. This one small laser welding tool combines cleaning, laser cutting, and laser welding machine capabilities in one system. Before welding: it lets you easily and fast remove oil, corrosion, and coatings During welding:it also lets you eliminate trash and discolouration Post-welding: it helps to cut precisely on several metal sheets including stainless steel, aluminum, and titanium “This tool gives the efficiency i need.” — Davon, Engineer Key Characteristics of the Welding Machine […]

レーザーマーキングは正確なQRコードを生成できる

Our digital environment depends much on QR codes. For businesses wanting to create QR codes, laser marking technology now is the go to product. This machine is able to laser mark barcodes and QR codes easily with high precision. Characteristics make laser marking stand out Laser marking machines have one major benefit in their adaptability. On many various materials, including metals, polymers, ceramics, and glass, they can create marks. This extensive applications allows businesses to apply QR codes and barcodes for laser engraving all kinds of products without regard to materials. All of the following are applicable: glass marking acrylic marking metal marking plastic marking wood marking

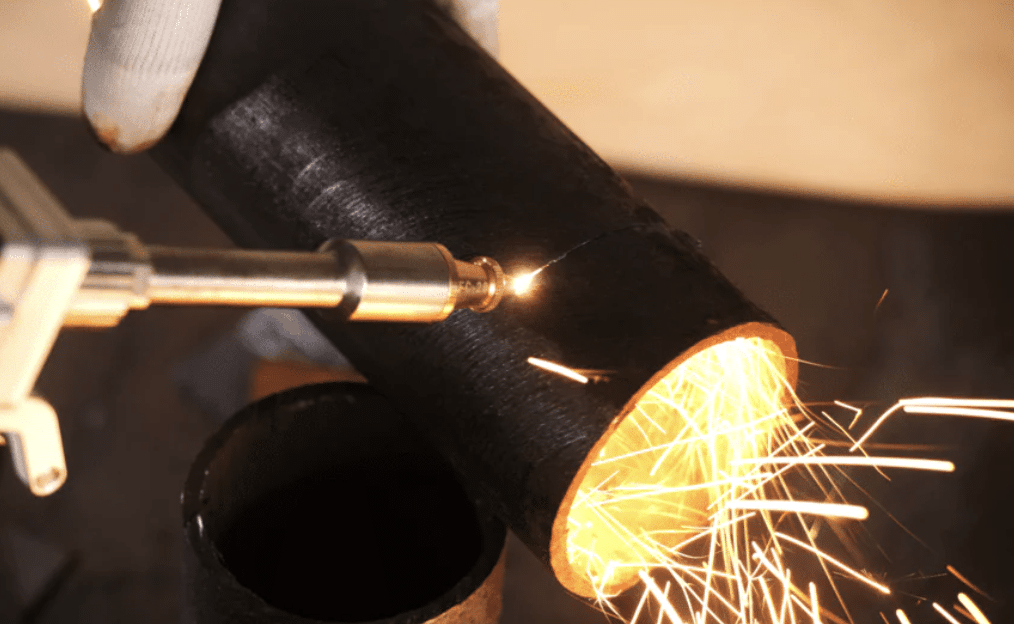

ハンドヘルドレーザー溶接機の長所と短所

Table of Contents Handheld laser welding machines have thoroughly reshaped the welding industry. They are state-of-the-art and portable devices that join materials in a meticulous and efficient way. These compact machines benefit from cutting-edge laser technology to weld metals and thermoplastics with almost no distortion and spatter. A plethora of industries—including automotive, aerospace, jewelry, and electronics—benefit from handheld laser welding machines because of their top-notch results and minimized heat-affected zones. These portable and versatile devices can handle a broad spectrum of materials and applications, which makes them a favorable option for intricate welding purposes. In our comprehensive post today, we aim to discuss integral advantages and disadvantages of handheld laser […]

米国のベストレーザー溶接機メーカー15社

Table of Contents What is a Laser Welding Machine? A laser welding machine is a state-of-the-art manufacturing tool that employs concentrated laser beams to fuse materials. The machine is broadly recognized for its unquestionable precision, speed, and versatility. It is widely used in industries such as automotive, aerospace, electronics, and medical devices. Laser welding machines come with a set of critical components: – Laser Source: This component generates the laser beam, which is commonly fiber, CO2, or Nd:YAG (Neodymium Yttrium Aluminum Garnet). – Optical System: This system focuses the laser meticulously on the material. – Control System: This system is responsible for managing the laser’s power, speed, and pulse duration. […]

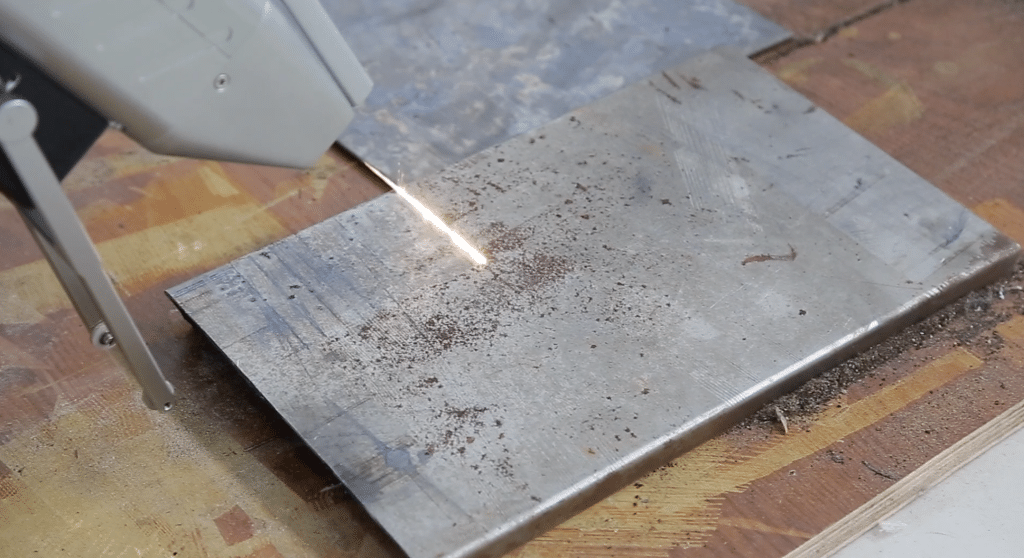

レーザー切断機はどのような材料を切断できますか?

Table of Contents Laser cutters are recognized as revolutionary tools in a broad spectrum of industries as they deliver the utmost precision and efficiency in cutting and engraving diverse materials. These machines converge concentrated beams of light before they can vaporize or melt materials to craft the most delicate and intricate designs with almost no waste. Precise laser cutters are employed for projects that demand clean, sharp edges of materials such as wood, metals, fabrics, and more. They are presented in different types so they can handle cutting needs for various materials. In our post today, we intend to discuss a set of materials that laser cutters can or cannot […]

ディープクリーニング後のレーザークリーニングは必要ですか?

Table of Contents The cleaning industry has faced considerable innovations throughout recent years. Laser cleaning machines are one of these notable innovations. It is a precise and eco-friendly cleaning technique that employs high-energy lasers to remove contaminants without harming the base material. Deep cleaning techniques depend on abrasives or chemicals; however, laser cleaning machines come with a non-contact essence that makes them a wonderful choice for sensitive surfaces. That’s why we decided to craft this post where we aim to discuss laser cleaning machines, how they work, their key elements, how they are different from deep cleaning, and more. What is a Laser Cleaning Machine? A laser cleaning machine […]