Green Power, Precision Welding – Kuntai Laser helps the new energy industry flourish

Against the backdrop of the global transition to a low-carbon economy, the new energy industry is developing at an unprecedented pace. As a leading manufacturer of laser welding machines, Kuntai Laser is committed to providing customers with high-quality, high-performance laser welding solutions. Today, we will explore how laser welding machines are playing a key role in the new energy sector. PART 1 Application scenarios of laser welding in the field of new energy 1. Power Battery Manufacturing: Guardian of Safety and Performance In the production of power batteries, laser welding technology has deeply penetrated into various key links: 2. Liquid cooling plate and box welding: Precision connection of new energy […]

Japanese customer | August 2025, Effect testing of new equipment in the factory

Recently, our company was honored to welcome a customer from Japan to conduct an on-site test of our laser marking machine for bicycle brake brackets and to evaluate the performance of our newly developed electric marking machine. During the customer’s visit, our engineers accompanied them throughout and provided technical support. The laser marking machine demonstrated excellent results on the bicycle brake bracket, producing clear, precise, and durable marks that fully met the customer’s high standards. Furthermore, our new electric marking machine’s ease of operation, high efficiency, and consistent marking quality earned high praise from the customer. After a successful demonstration, the Japanese customer expressed great satisfaction with the equipment’s performance […]

Indian customer | August 2025, Factory visit and on-site inspection

Today, we had the pleasure of welcoming a client from India to our factory for an in-depth, on-site inspection. The client expressed a strong interest in purchasing our fiber laser marking machine, seeking a comprehensive understanding of its performance and application capabilities. Our sales team provided a detailed presentation on the machine’s technical specifications, functional features, and operational advantages, covering aspects such as marking precision, speed, adaptability to various materials, and long-term reliability. To further demonstrate our manufacturing capacity, we guided the client through other production and processing workshops within our facility, showcasing our advanced equipment, quality control processes, and commitment to technological innovation. The visit concluded with productive discussions, […]

Algerian customers | August 2025, On-site inspection and selection of desired equipment

Today, a customer from Algeria visited our company for an on – site inspection, aiming to select suitable equipment for their nameplate printing needs. Accompanied and meticulously explained by our sales staff, the customer conducted comprehensive tests on the fiber laser marking machine and the pneumatic marking machine, and finally reached a cooperation intention to purchase the fiber laser marking machine. This cooperation not only demonstrates the excellent quality of our equipment but also lays a solid foundation for the in – depth cooperation between both parties in the future. Equipment Testing: Fiber Laser Marking Machine Has Significant Advantages During the inspection, the customer focused on the effect and efficiency […]

Chicago customer | July 2025, On-Site Acceptance of Nameplate Auto-Feeding Marking Machine

We were honored to welcome a valued client from Chicago to our facility for the on-site acceptance of a recently ordered Automatic Nameplate Marking Machine. This visit marked an important step in our collaboration and demonstrated our commitment to product quality and customer satisfaction. During the acceptance process, our engineering team provided the client with comprehensive technical support, addressing all operational and performance-related inquiries with precision and patience. Every concern raised by the client was thoroughly answered, ensuring full confidence in the machine’s capabilities and compliance with the required specifications. In addition to the acceptance procedure, the client was accompanied by our sales representatives on a tour of our manufacturing […]

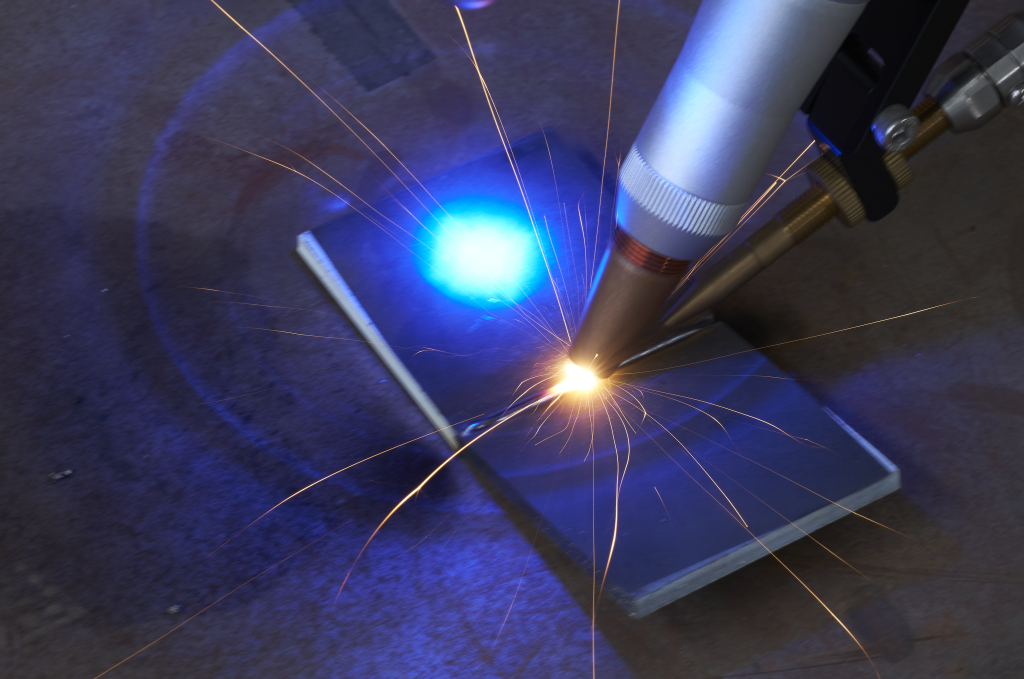

Laser Drilling and Cutting of Glass: The Emerging Trend in Precision Manufacturing

In recent years, laser technology has become an increasingly preferred method for glass drilling and cutting across a wide range of industries, including electronics, automotive, medical devices, and consumer goods. As the demand for high-precision, clean-edge, and minimal-damage processing grows, laser solutions are rapidly replacing traditional mechanical methods. Why Laser Cutting of Glass Is Becoming a Trend? Modern electronic devices and high-performance optical components require micro-scale processing with extreme accuracy. Traditional cutting methods, such as mechanical scribing or waterjet cutting, often fall short in delivering the precision and edge quality needed in these applications. With the widespread use of ultra-thin glass, chemically strengthened glass, and specialty coatings, there is a […]

Laser Creates Eco-Friendly Labels for Fruits and Vegetables

Laser marking technology offers a sustainable, safe, and innovative solution for labeling fruits and vegetables. By replacing traditional stickers, inks, or plastic packaging, laser systems gently etch essential product information—such as origin, variety, dates, or QR codes—directly onto the skin of the produce without affecting its freshness, taste, or shelf life. This non-contact, chemical-free process not only reduces material waste and adhesive residue but also aligns with global trends toward environmentally responsible food packaging. Advantages of Laser Technology in Fruit and Vegetable Labeling As consumer demand for clean labeling and sustainable packaging grows, laser technology stands out as a modern, reliable, and eco-conscious choice for the fresh produce industry.

Application of Laser Cleaning Machines in Shipbuilding and Ship Maintenance

Laser cleaning technology, utilizing high-power continuous fiber lasers integrated with robotic arms and mobile power stations, provides an advanced solution for the efficient removal of thick rust and large-area corrosion on ship surfaces. Compared with traditional methods such as sandblasting and chemical cleaning, laser cleaning offers a non-contact, environmentally friendly, and precise alternative that minimizes substrate damage and eliminates secondary pollution. The adoption of multi-axis robotic systems enables automated and flexible cleaning of complex ship geometries, ensuring uniform cleaning results and significantly improving operational efficiency. The system’s high-power laser source delivers rapid cleaning speeds, effectively restoring heavily corroded steel surfaces while reducing downtime and labor costs. Additionally, the mobile power […]

Lithium battery welding | a major highlight of the new energy industry

Laser welding and laser spot welding, with their advantages of high precision, minimal heat-affected zones, and aesthetically pleasing welds, have been widely applied in the production of new energy and lithium batteries, including tab welding, casing sealing, and electrode group connections. These technologies significantly enhance battery reliability and consistency. In the future, driven by the rapid growth of the electric vehicle and energy storage markets, laser welding will evolve toward higher automation, faster processing speeds, and greater stability. Integrated with intelligent inspection systems, it will enable efficient, intelligent, and defect-free battery manufacturing, providing robust technical support for the new energy industry.

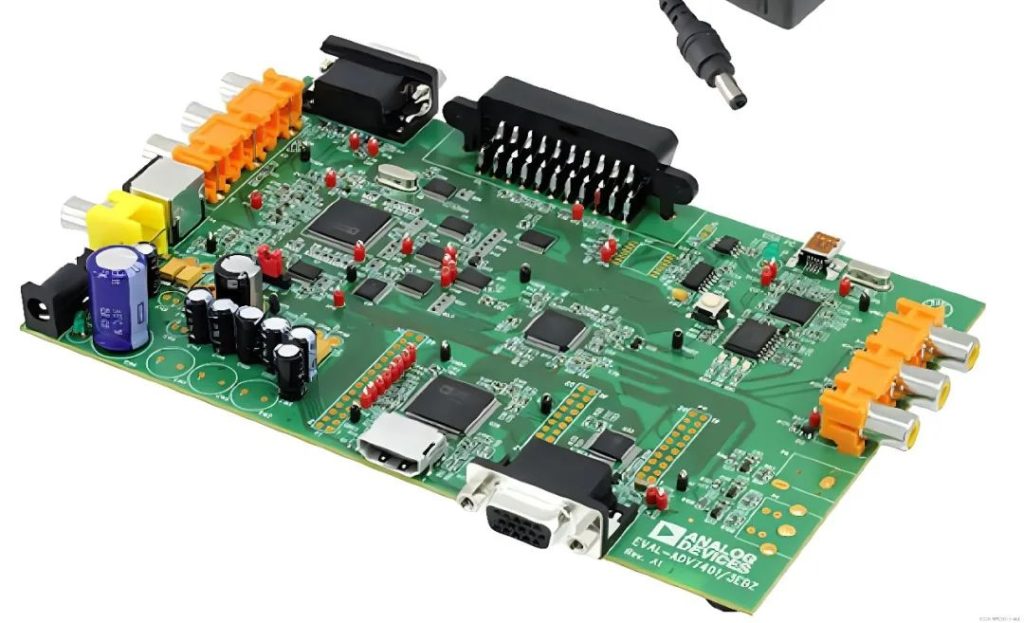

Laser Marking Systems: The Precision Engraving Solution for the PCB Industry

As demands for precision and traceability grow in PCB production, traditional marking methods can no longer meet the requirements for accuracy, durability, and environmental safety.Laser marking, with its non-contact process and high precision, enables micron-level engraving of codes and patterns on PCB surfaces—efficiently, permanently, and without pollution. This article outlines the core principles, advantages, and prospects of laser marking as a key technology in modern electronics manufacturing. · PCB’s “Smart ID Card” Generator 1. Permanent marking of proprietary information Each PCB has its own “ID card” – QR code, serial number, LOGO. Traditional ink printing is easy to wear, while laser marking directly “burns” permanent marks, which cannot be wiped […]