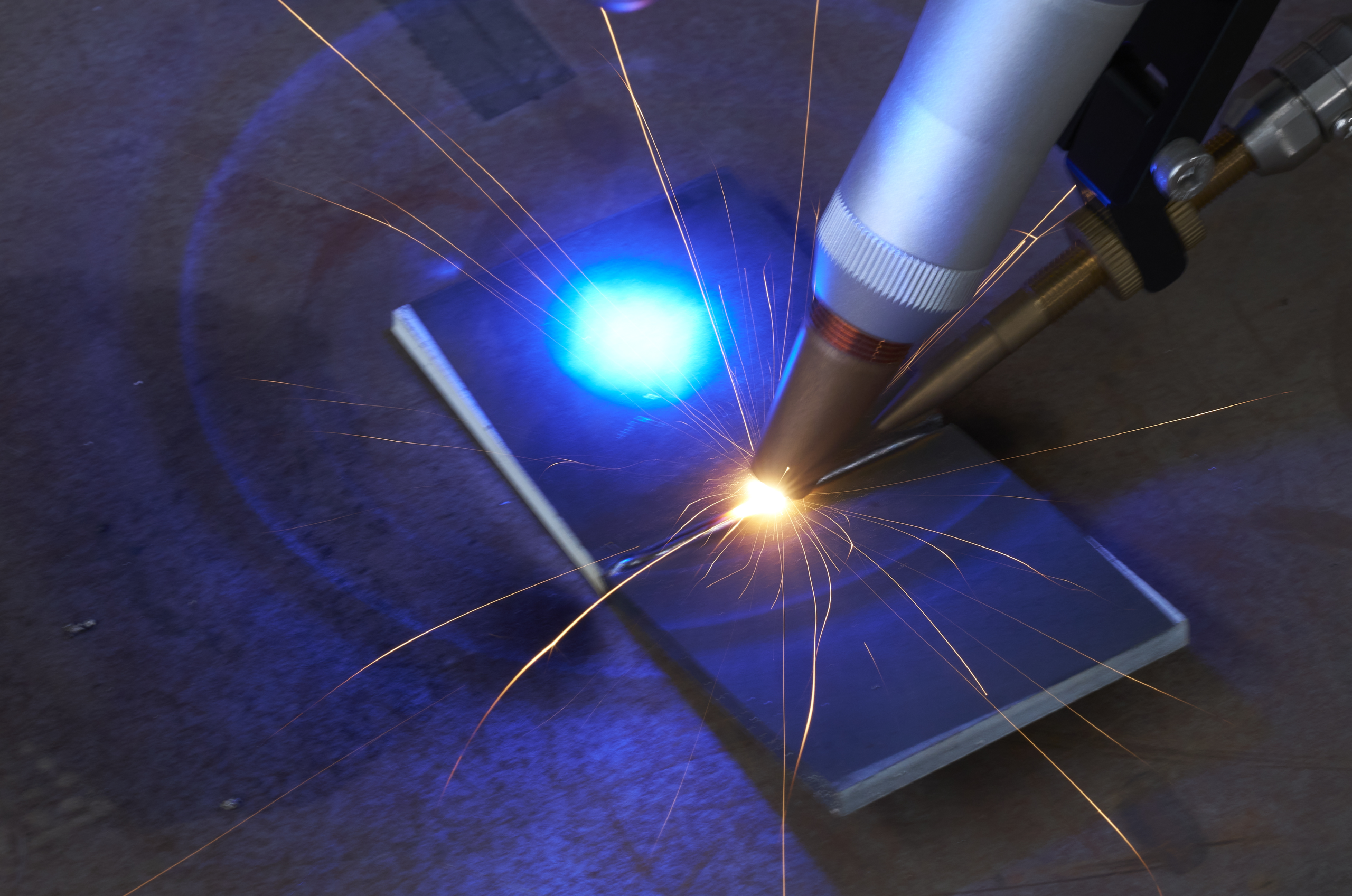

Laser cleaning technology, utilizing high-power continuous fiber lasers integrated with robotic arms and mobile power stations, provides an advanced solution for the efficient removal of thick rust and large-area corrosion on ship surfaces. Compared with traditional methods such as sandblasting and chemical cleaning, laser cleaning offers a non-contact, environmentally friendly, and precise alternative that minimizes substrate damage and eliminates secondary pollution.

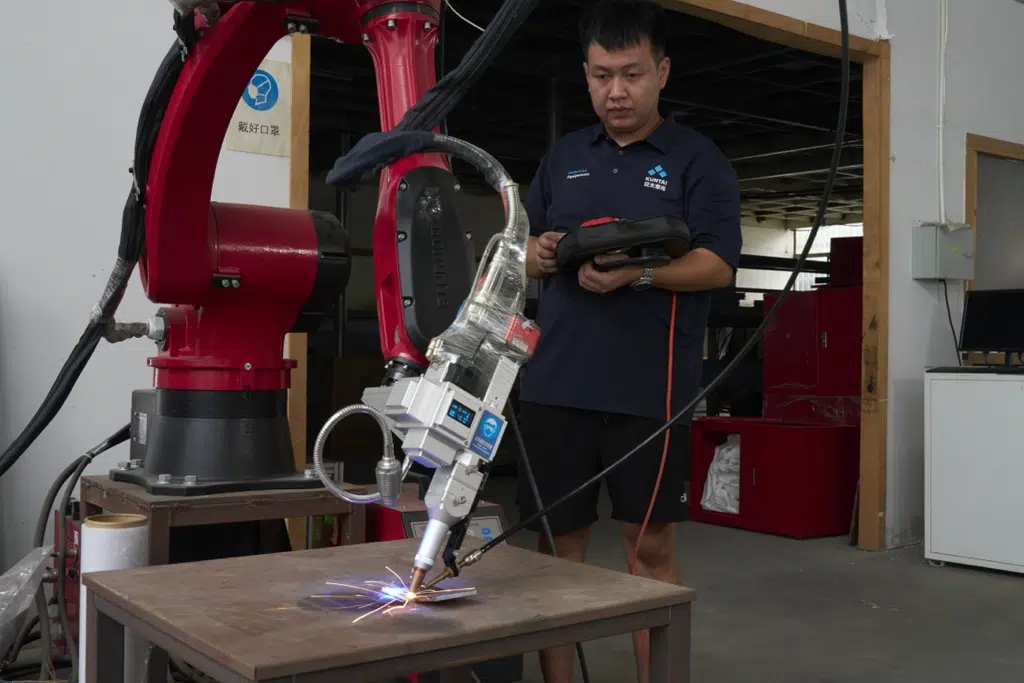

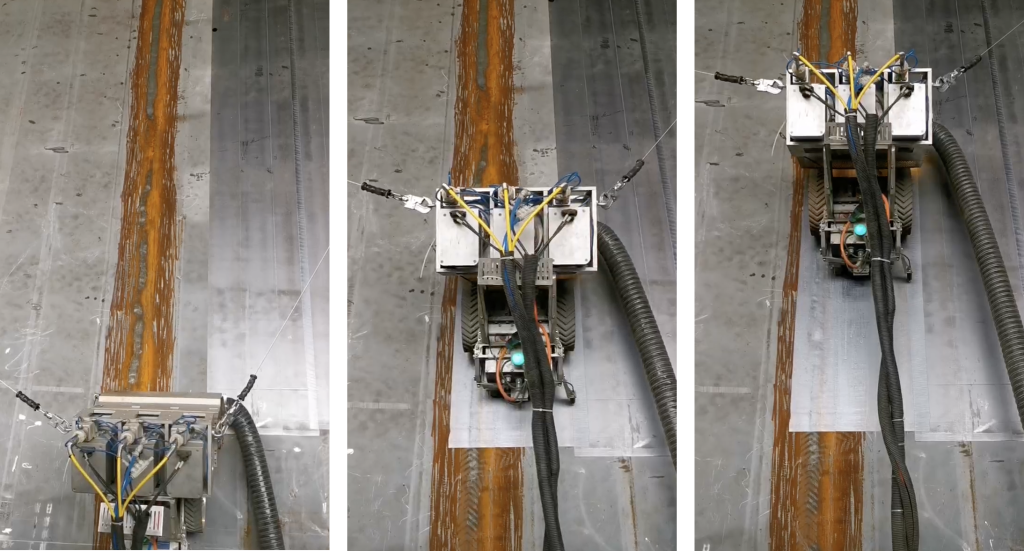

The adoption of multi-axis robotic systems enables automated and flexible cleaning of complex ship geometries, ensuring uniform cleaning results and significantly improving operational efficiency. The system’s high-power laser source delivers rapid cleaning speeds, effectively restoring heavily corroded steel surfaces while reducing downtime and labor costs. Additionally, the mobile power station configuration allows for easy deployment in shipyards and dock environments, ensuring stable and continuous operation even in challenging outdoor conditions.

By extending the service life of ship structures and reducing maintenance frequency, laser cleaning technology contributes to lower lifecycle costs and improved safety in maritime operations. Its capability to handle diverse areas such as hull exteriors, decks, ballast tanks, and propellers makes it an indispensable tool for modern ship maintenance and refurbishment.