In recent years, laser technology has become an increasingly preferred method for glass drilling and cutting across a wide range of industries, including electronics, automotive, medical devices, and consumer goods. As the demand for high-precision, clean-edge, and minimal-damage processing grows, laser solutions are rapidly replacing traditional mechanical methods.

Why Laser Cutting of Glass Is Becoming a Trend?

- Rising Demand for Precision

Modern electronic devices and high-performance optical components require micro-scale processing with extreme accuracy. Traditional cutting methods, such as mechanical scribing or waterjet cutting, often fall short in delivering the precision and edge quality needed in these applications.

- Growth of Thin and Specialty Glass

With the widespread use of ultra-thin glass, chemically strengthened glass, and specialty coatings, there is a growing need for non-contact, thermally controlled processing. Laser cutting is ideally suited for these materials due to its flexibility and precision.

Advantages of Laser Glass Drilling and Cutting

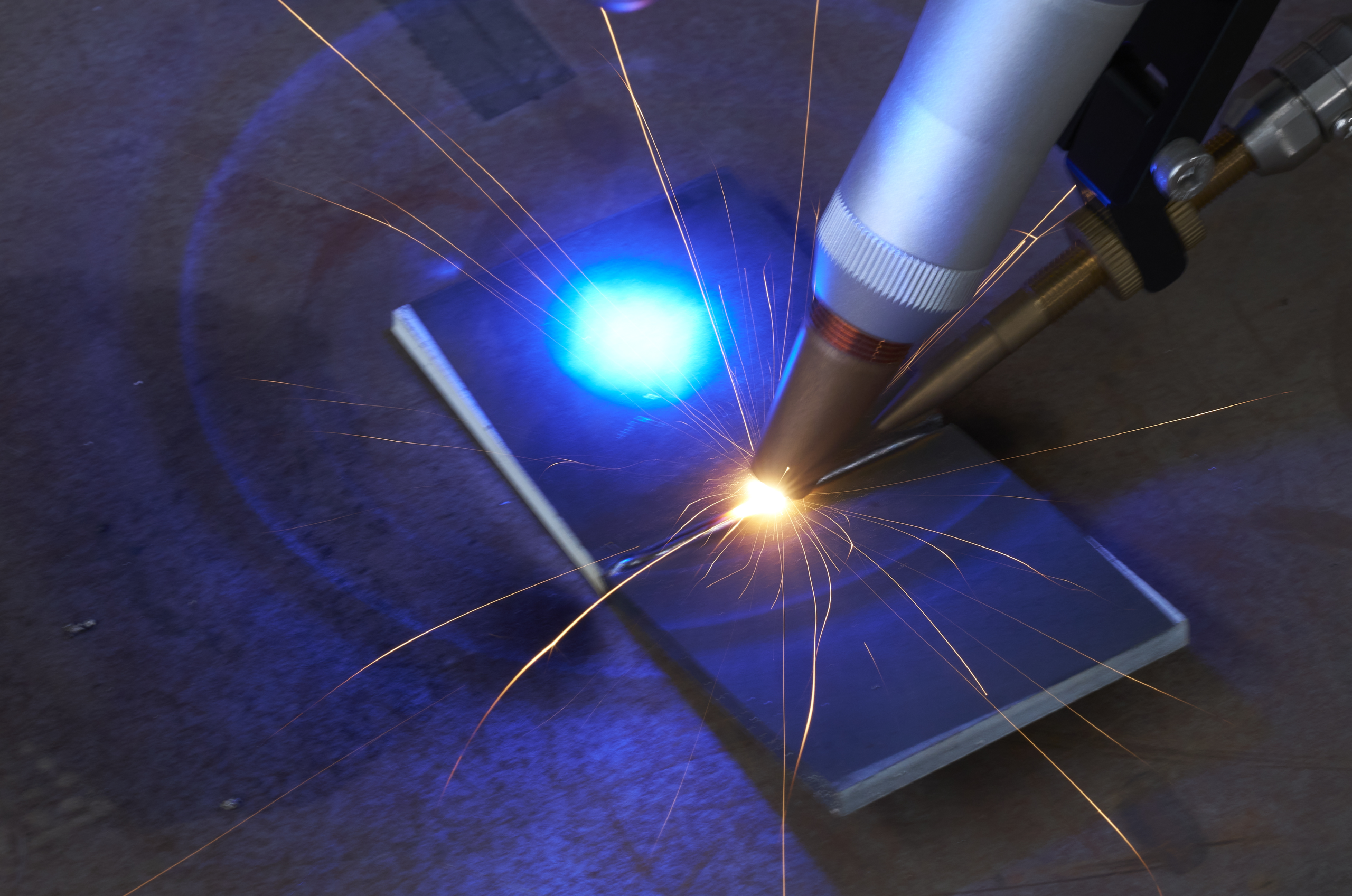

- Non-Contact Processing

Laser cutting is a non-contact method, meaning there is no physical force applied to the glass surface. This significantly reduces the risk of micro-cracks, chipping, and material stress.

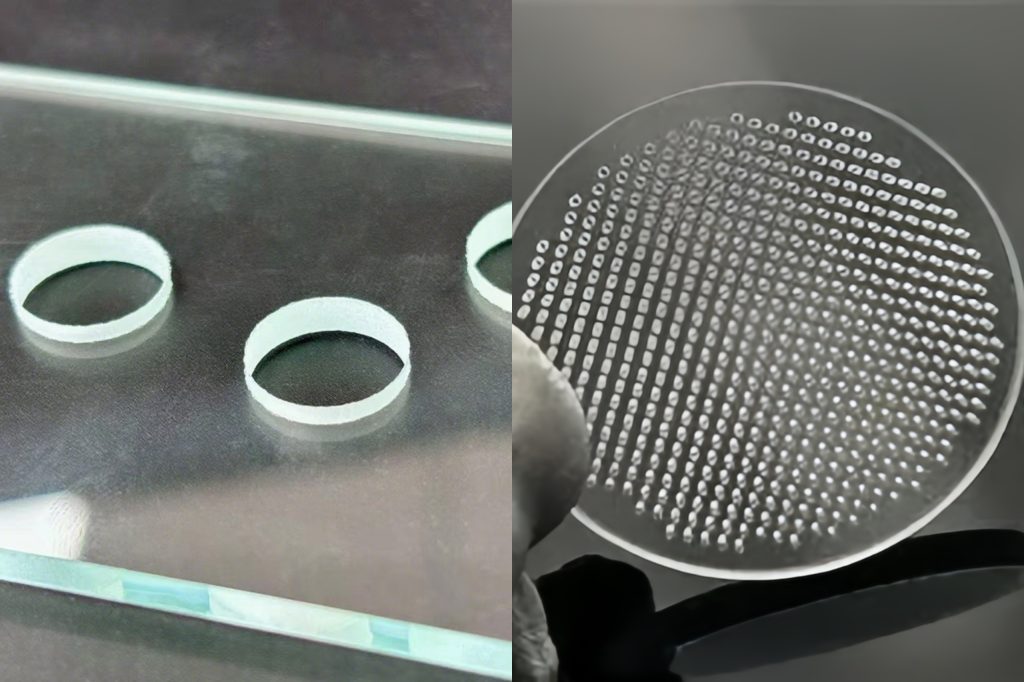

- High Precision and Clean Edges

Laser systems can produce extremely fine cuts and holes with smooth edges, minimizing the need for post-processing and improving the structural integrity of the finished product.

- Flexibility in Shape and Design

Complex geometries, curved paths, and small-diameter holes can be easily achieved with laser processing, making it ideal for customized and intricate applications.

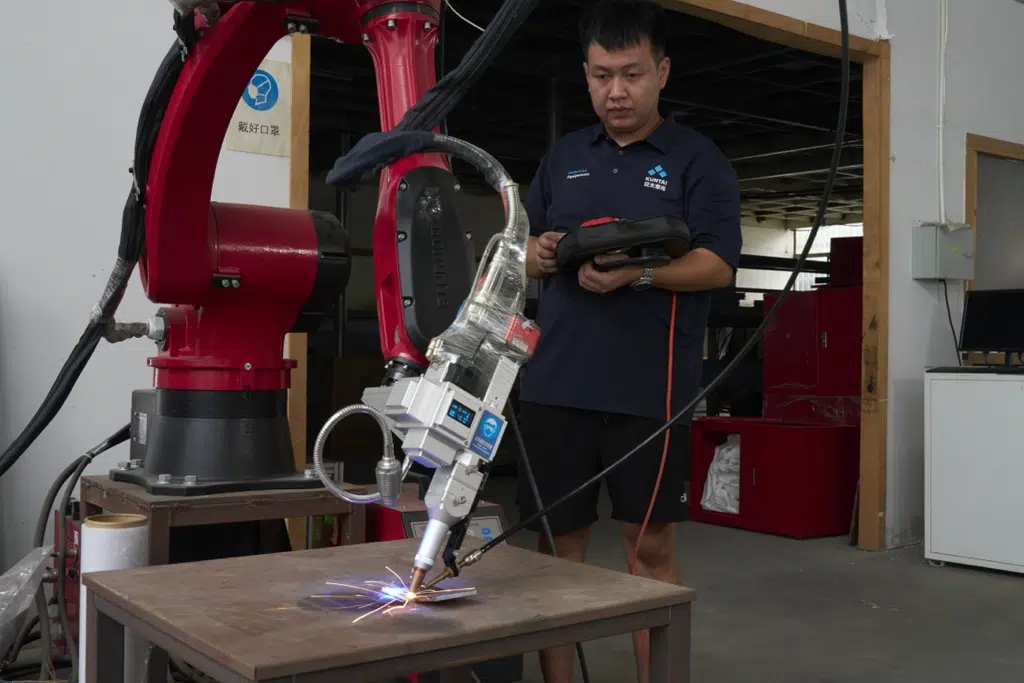

- Improved Efficiency and Automation

Laser systems are highly compatible with automated production lines, increasing throughput while maintaining consistent quality.

- Minimal Waste and Environmental Impact

With precise control and low material loss, laser processing contributes to more sustainable manufacturing practices.

As industries continue to demand greater accuracy, efficiency, and material performance, laser drilling and cutting of glass are proving to be indispensable. With our advanced laser systems and expertise, we provide tailored solutions that meet the evolving needs of modern manufacturing. Contact us today to learn how our laser technology can enhance your production capabilities.