Against the backdrop of the global transition to a low-carbon economy, the new energy industry is developing at an unprecedented pace. As a leading manufacturer of laser welding machines, Kuntai Laser is committed to providing customers with high-quality, high-performance laser welding solutions. Today, we will explore how laser welding machines are playing a key role in the new energy sector.

PART 1 Application scenarios of laser welding in the field of new energy

1. Power Battery Manufacturing: Guardian of Safety and Performance

In the production of power batteries, laser welding technology has deeply penetrated into various key links:

- Battery Cell Manufacturing: Laser welding plays a key role in tab welding. Tabs are the parts of a battery cell that connect the positive and negative electrodes to the external circuitry. The quality of the welding directly impacts the battery’s charge and discharge performance and safety. Laser welding enables precise and efficient connection of tabs to the battery cell body, with high welding speeds, a minimal heat-affected zone, and minimal damage to the cell’s internal structure.

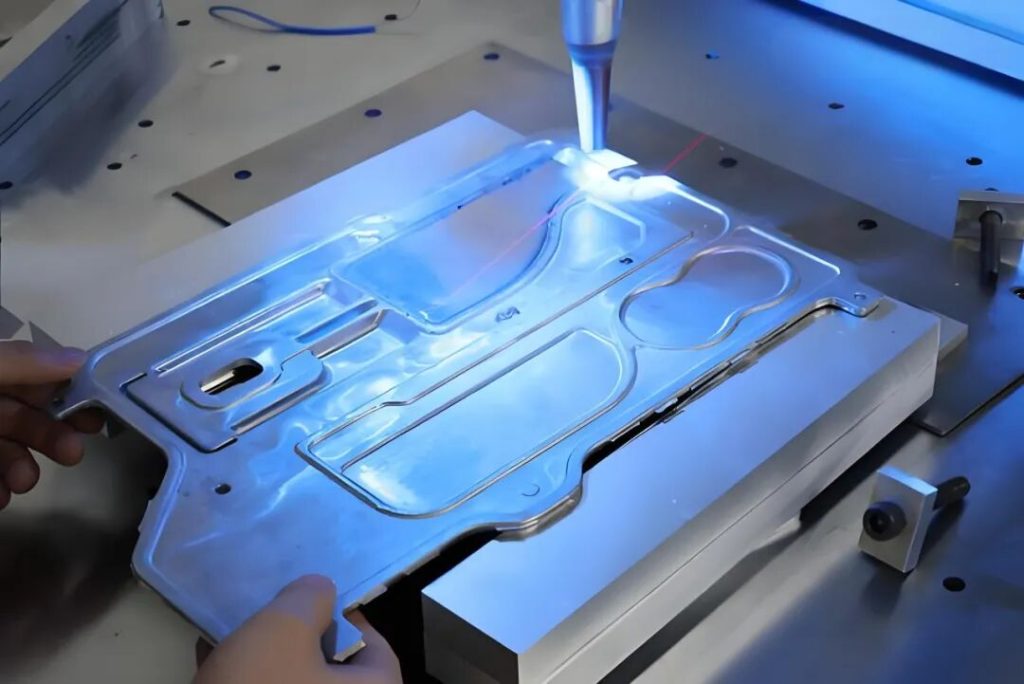

- Module and Pack Assembly: During module welding, laser welding enables precise positioning and welding, ensuring secure connections between the cells within the module and stable current transmission. In pack welding, laser welding meets even higher requirements for weld precision, strength, and sealing, improving the overall performance and safety of the battery system.

2. Liquid cooling plate and box welding: Precision connection of new energy cooling system

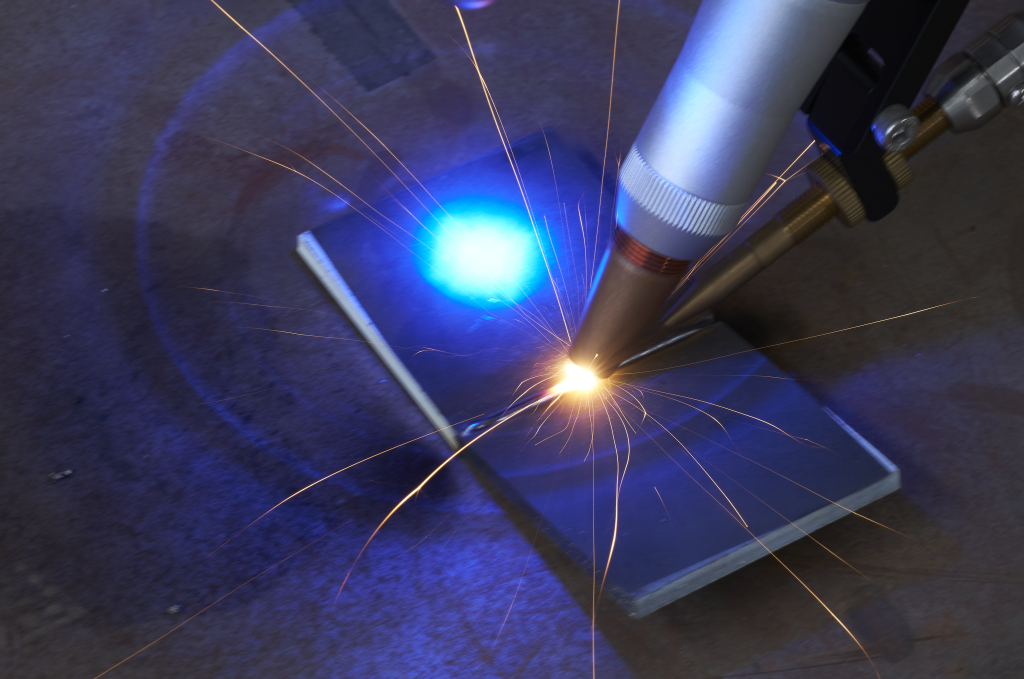

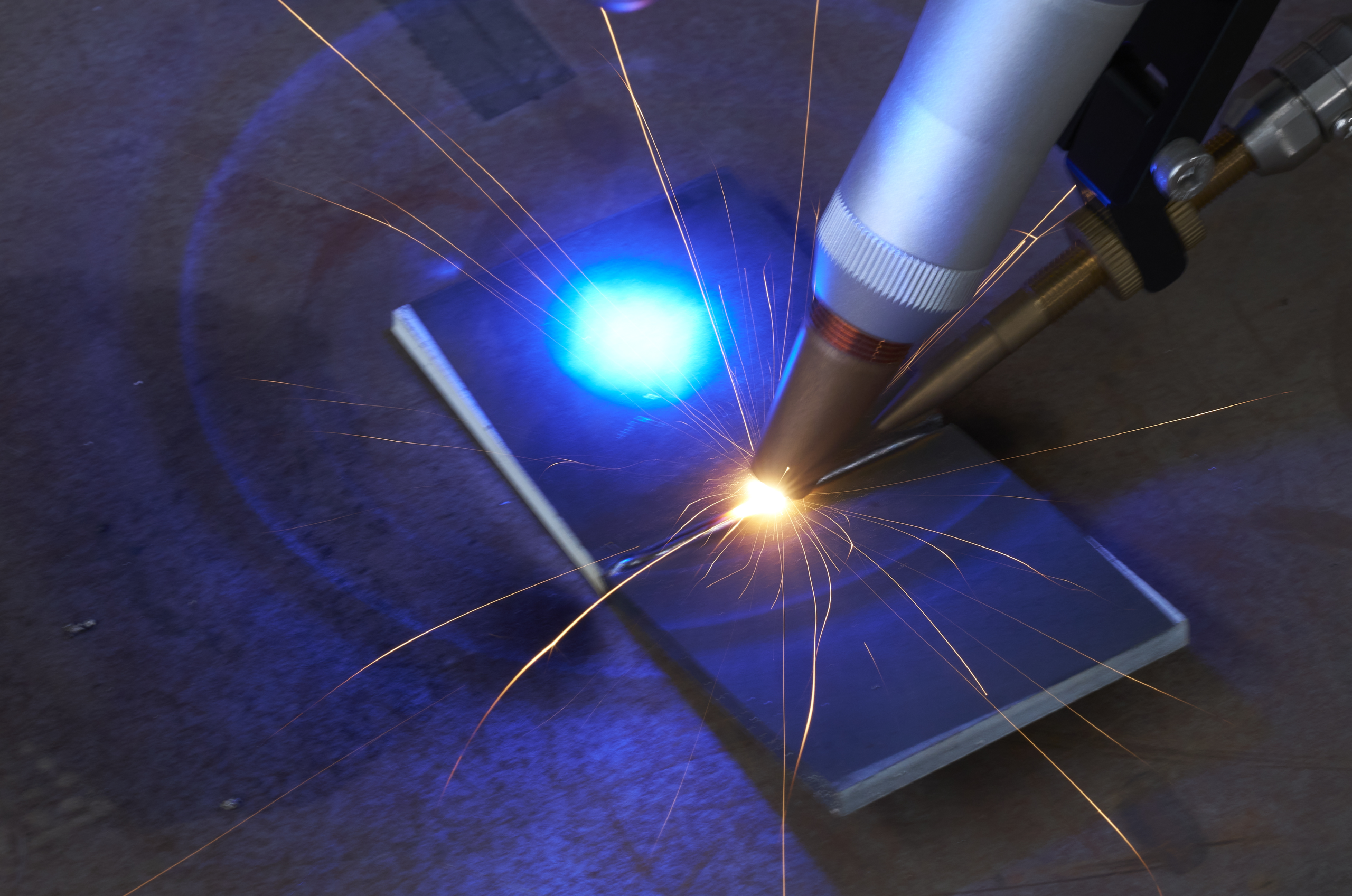

Faced with the urgent demand for liquid-cooled radiators in the new energy industry, laser welding of new energy cabinets has significant advantages: no smoke, exhaust gas or other harmful substances are produced during the welding process, which meets environmental protection requirements; the welds are smoother and smaller, and the appearance is more beautiful; the heat-affected zone is small, and the welding deformation is small, which greatly improves the welding quality and reliability.

3. Solar energy and hydrogen energy: Clean energy welding solutions

- Solar panel manufacturing: Laser welding enables high-precision welding between solar cells. It welds quickly, creates small weld points, and does not damage the cells, ensuring the panel’s power generation efficiency and reliability. Laser welding also enables fast and secure frame welding, improving the panel’s overall structural strength and sealing.

- Hydrogen fuel cell manufacturing: Laser welding can achieve high-precision welding in bipolar plate welding, ensuring the sealing and conductivity of the bipolar plates, improving the performance and life of hydrogen fuel cells. For the packaging welding of membrane electrode assemblies, laser welding ensures its sealing and stability, improving the power generation efficiency of hydrogen fuel cells.

4. Motors and Components: The Joints of New Energy Vehicles

In new energy vehicle drive motors and industrial servo motors, rotors operate under high speed, temperature, and pressure, requiring high strength and conductivity. Traditional argon arc or resistance welding causes large deformation and porosity. The laser welding system, with a rotating double-station design, separates loading from welding, enabling simultaneous operations and boosting efficiency. In new energy vehicle parts, laser welding applies to complex structures such as seat frames, small tables, leg rests, and housings like control boxes and battery boxes, ensuring strength, sealing, and safety.

PART 2 Kuntai Laser Welding Machines Enable Efficient and Intelligent Manufacturing

The transformation of traditional manufacturing is urgent. Automation, intelligence, and reduced labor are key to efficiency and competitiveness. Welding, as a critical process, directly affects overall performance. Current pain points include low efficiency, inconsistent quality, labor shortages, and poor environments. Traditional automated welding, such as arc welding, still lacks precision and speed.

Kuntai laser solutions:

- Laser welding is several times faster than traditional welding, significantly improving production line cycle time and shortening delivery cycles.

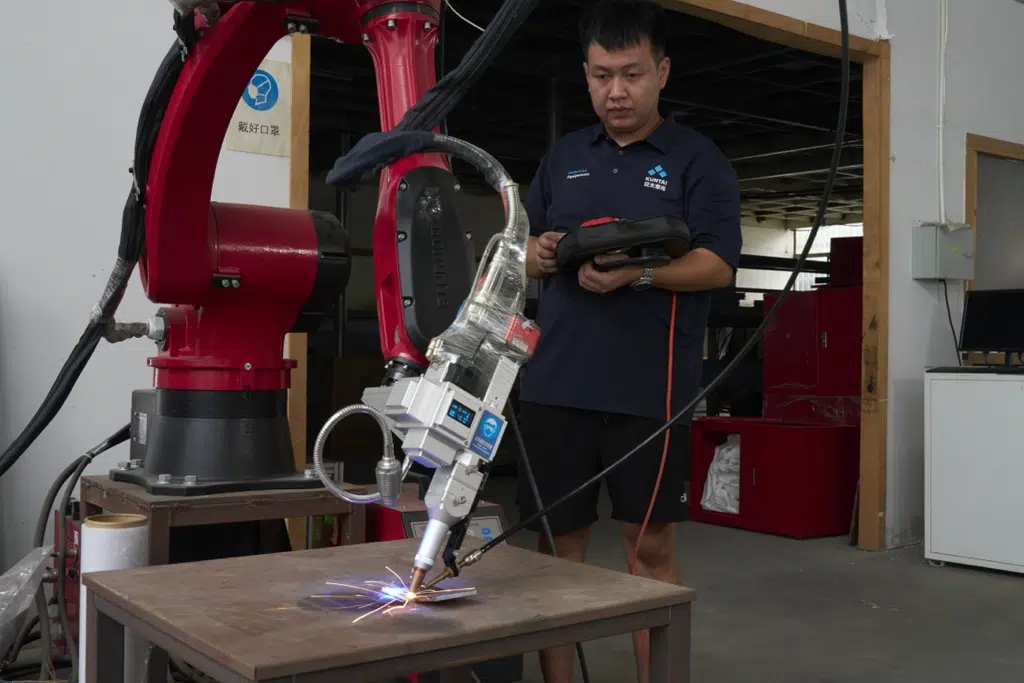

- Kuntai laser welding heads are seamlessly integrated with mainstream industrial robots to create highly flexible and high-precision automated welding workstations or production lines, achieving 24-hour stable operation.

- The mature process package and user-friendly operation interface reduce the dependence on advanced welders, allowing novices to quickly get started and stably output high-quality welds.

- Compared with argon arc welding, it produces very little smoke and dust, creating a cleaner working environment and conforming to the trend of green manufacturing. It also has higher energy efficiency.

- Provides equipment networking and data interface, supports access to the factory MES system, and realizes digital management and predictive maintenance of the welding process.

In new energy manufacturing, laser welding has grown into a core production technology. Its precision, efficiency, and eco-friendly features meet the industry’s dual pursuit of quality and efficiency. As the market expands and technology advances, laser welding will drive further innovation. For manufacturers, upgrading to laser welding brings advantages in quality, efficiency, and cost control. Kuntai Laser will continue to advance in this field, offering precise, intelligent, and reliable solutions.